Smelting is the backbone of metal production, but it comes with challenges such as extreme heat, abrasive dust and unpredictable conditions. Traditionally, operators relied on indirect measurements and periodic manual inspections, methods that often-meant downtime, safety risks and limited visibility.

The latest furnace cameras change the game by offering continuous, real-time imaging inside the furnace without compromising safety or production.

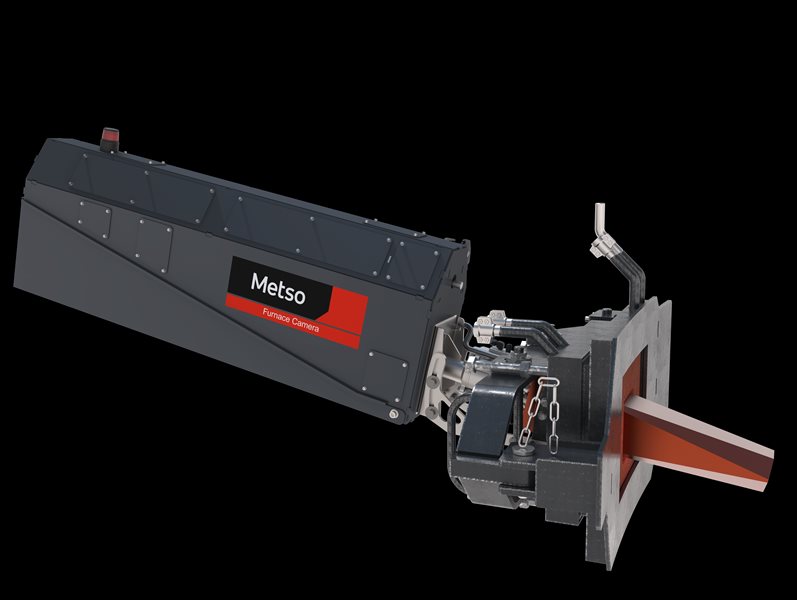

Recent innovations have made furnace cameras more robust and intelligent than ever before. Advanced cooling systems now protect optics from temperatures exceeding 2200 degrees Celsius, extending equipment life and reducing maintenance needs. Automated retraction mechanisms also ensure cameras withdraw safely during power or cooling failures, adding an extra layer of security. Integration with plant automation systems allows operators to view live feeds and thermal data directly in control systems, while AI-driven analytics are emerging to enable predictive maintenance and anomaly detection based on image patterns.