The original cooling elements were installed in 2007, underscoring the design’s reliability. Late in October 2024, Kosaka commissioned Metso to manufacture and supply a replacement set. All elements were manufactured and shipped in time for Kosaka’s scheduled maintenance shutdown in September 2025 so that they could be installed in time without impact on planned production.

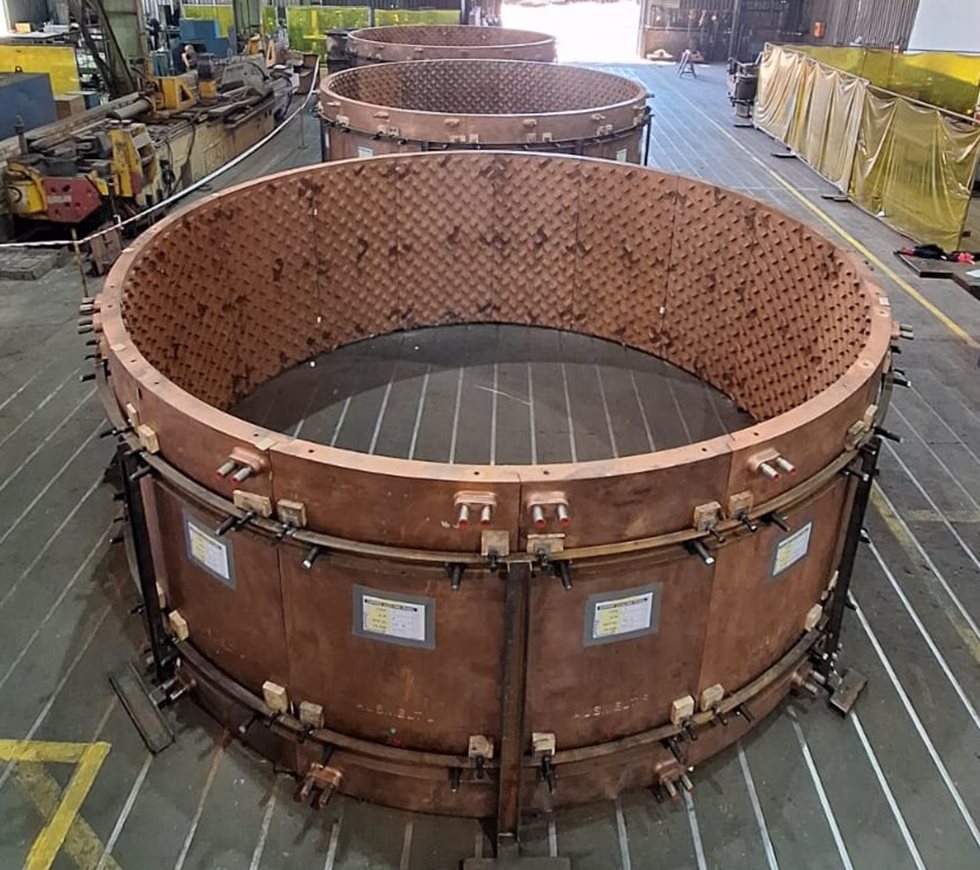

Precision manufacturing and quality assurance

The new elements underwent rigorous quality testing and trial fitting to ensure compatibility with Kosaka’s existing furnace. During this phase, technical representatives from Kosaka visited the manufacturing facility alongside Metso’s engineering and quality team to oversee inspections and observe the trial fitting firsthand.

“High quality manufacturing of copper cooling elements is absolutely critical to ensure they are fit for use in the aggressive environment of a TSL furnace,” says Neil Jacobson - Product Manager for Ausmelt TSL Smelting at Metso. “All elements are subjected to extensive testing and inspections to confirm composition, material properties, water flow capacity, pressure rating and dimensions. This ensures that on-site installation of the copper elements will go smoothly and that the panels will provide many years of reliable service.“