Comprehensive filtration portfolio

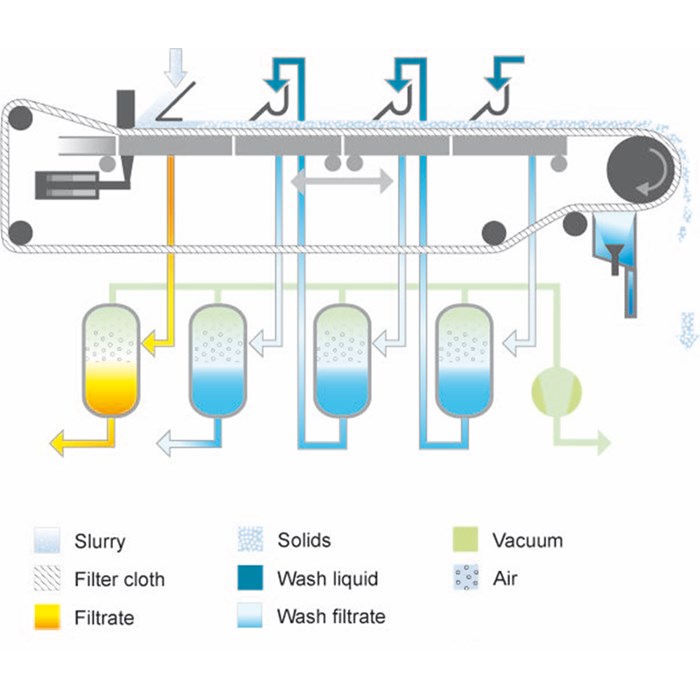

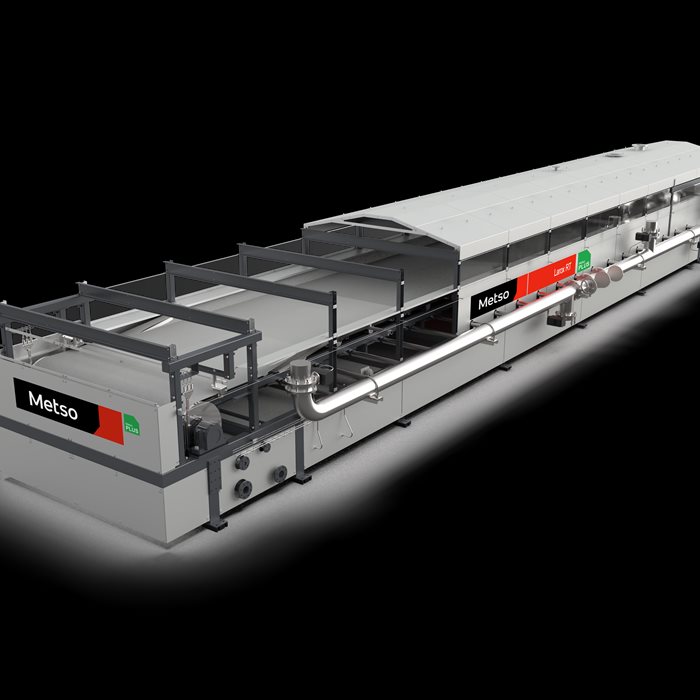

Beside the widely used Larox RT and Larox PF filters, Metso filtration has the broadest portfolio allowing to consider alternative filtration technologies like, but not limited to conventional filter presses, rubber belt and liquid polishing filters.