This article was first published on Mining.com in July 2025.

Higher energy consumption is often required, with both environmental and financial implications, especially in view of rising global energy prices. Mining industry statistics indicate that the entire mining industry consumes approximately 3.5% of total final energy consumption globally. Comminution (crushing and grinding) within that industry may account for up to 1% of that total, as per the CEEC International: Coalition for Minerals Efficiency - Opens in a new window

The additional processing needed to maintain production levels also leads to an increase in premature wear and tear on both equipment as well as wear and spare parts, resulting in excessive quantities of material sent to landfills. Replacing worn units with new machines and components also comes with a high carbon footprint, tied to the manufacturing process and fuel used in transport to site.

Facing the challenges of reducing energy usage as well as minimizing waste, miners are looking at diverse ways to optimize energy consumption throughout the mining process and to get more life from their parts.

However, it is not always so easy to make a start. One approach is to first look at the crushing process within the comminution stage. Modifications or improvements made at the primary or secondary crushing steps can have an immediate impact on sustainability and may also lead to gains further downstream.

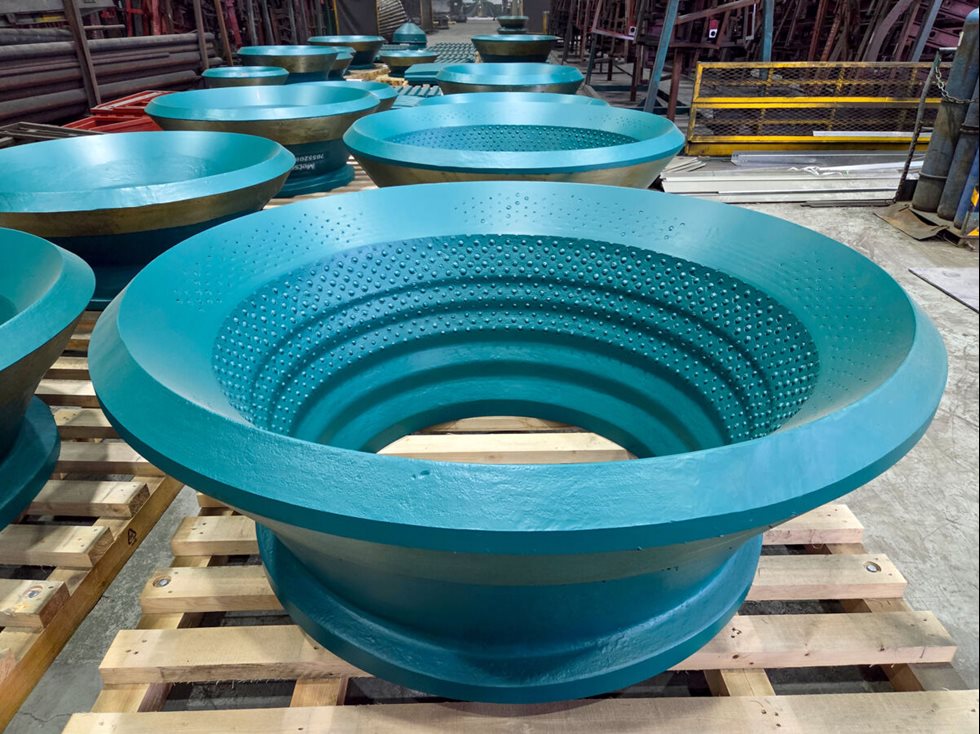

Unlocking the potential with crusher wear parts

When looking into the crushing circuit, wear parts offer a great opportunity to make a sustainable impact. Choosing crusher wear parts that extend the wear life can provide multiple benefits to your crusher, while also supporting sustainability targets.

Maximizing the lifetime of crusher wear parts results in less waste that needs to be managed and recycled. Fewer parts also need to be supplied, so sustainability benefits are seen throughout the supply chain from less production needed to CO2 savings from reduced foundry operations and transport of replacement wear parts.

As an example of more sustainable wear parts, Metso MX for cones - Opens in a new window can offer up to double the wear life in secondary cone crushing applications. This results in calculable and tangible sustainability benefits – half the wear parts needed, half the liner backings as waste, reduced manufacturing inputs such as water, energy and sand mold, and less transportation emissions.

What’s more, all maintenance activities require a great deal from site staff – they are time-intensive in terms of planning and implementation, require highly experienced personnel and have inherent risk exposure. Fewer change-outs mean a reduced need for all the activities linked to maintenance breaks and higher productive time for your crushers, which can impact profitability. High-risk activities can also be minimized with less frequent changeouts.