Many sites look first to equipment such as their grinding mills, primary crushers or ore sorting systems to explore ways to save energy. With water rapidly becoming a scarce resource, flotation cells, thickeners and tailings management strategies quickly come under the loop. But what about pumps? Installed at multiple points across a typical minerals processing facility, the way that a site or plant's pumps are selected, sized, operated, and maintained can all play a major role in managing energy and water consumption. Getting these factors right can also help control the wear and tear on slurry pumps and reduce the amount of worn pump liners, components and valves consumed.

To save energy, choose the right pump

When it comes to efficiency and energy savings, many sites select equipment from different suppliers. This has the hazard of suppliers building in a safety factor on the sizing or selection of their individual equipment. If each supplier builds in this factor, it can result in significant oversizing across the circuit. For example, if a pump is oversized it may operate less efficiently and wear faster than an optimally sized pump. In extreme examples, a pump may not even be able to achieve the application if the details used to size the pump are dramatically different from what exists at the site.

Choosing the right pump not only improves hydraulic efficiency but also lowers operational costs. For example, Metso’s latest slurry pumps offer up to 17% higher efficiency, translating into around 15% less energy consumption. More efficient pumps also last longer, which means less frequent maintenance, fewer spare parts, and reduced carbon footprint across the value chain. Metso’s PumpDim software is utilized to size and select the best pump for an application.

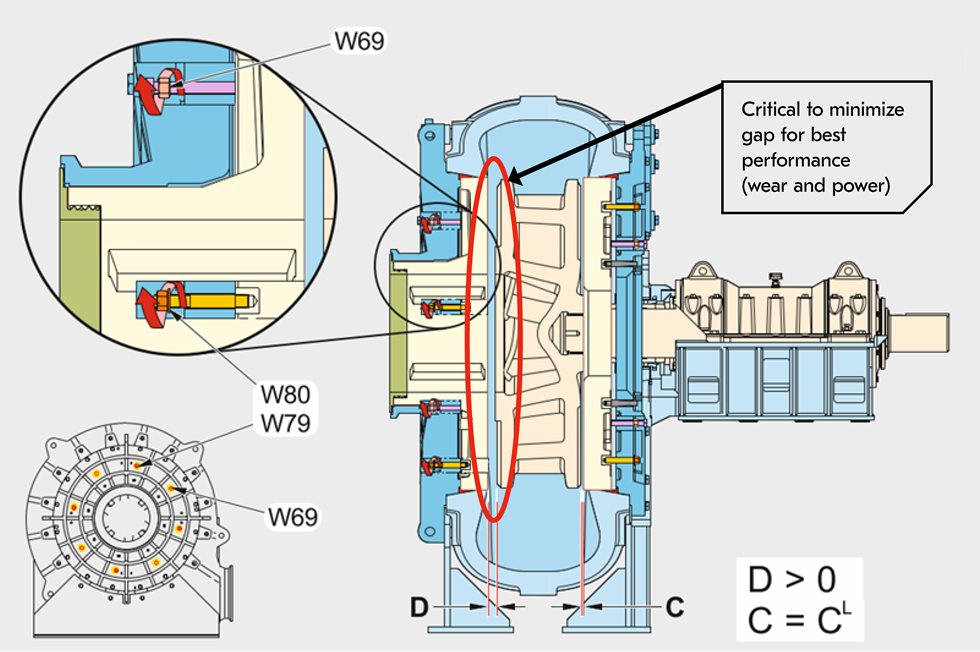

It doesn't just stop once a pump is selected. Operator actions can also have an impact on energy use. Maintaining tight internal clearances by adjusting the gap between the impellor inlet liner to avoid recirculation can result in increased uptime and additional energy savings (See Figure 1). Another underestimated but crucial feature of slurry handling is pipeline configuration and wear monitoring. Aspects such as inner diameter, pipeline configuration, and lining material have significant implications not only in the pipeline wear resistance, but in process stability and energy consumption.