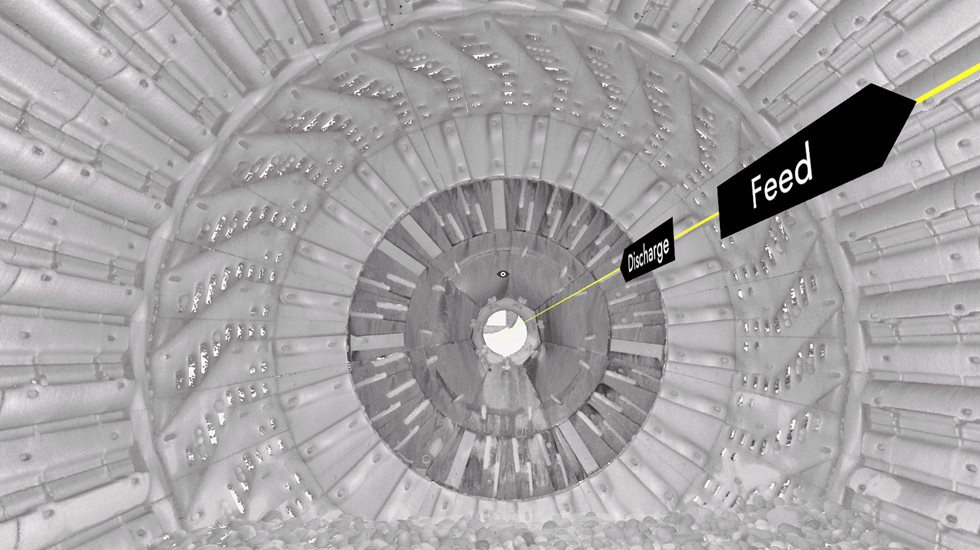

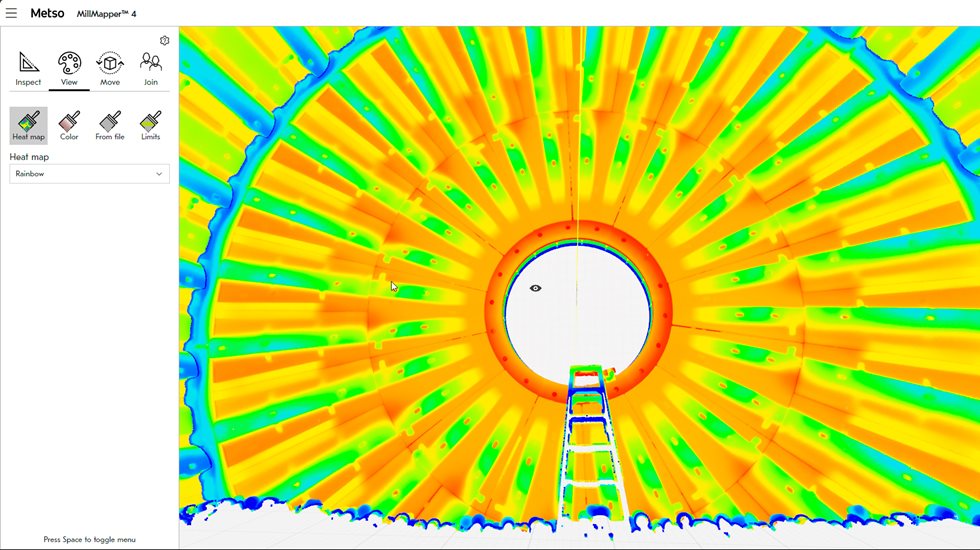

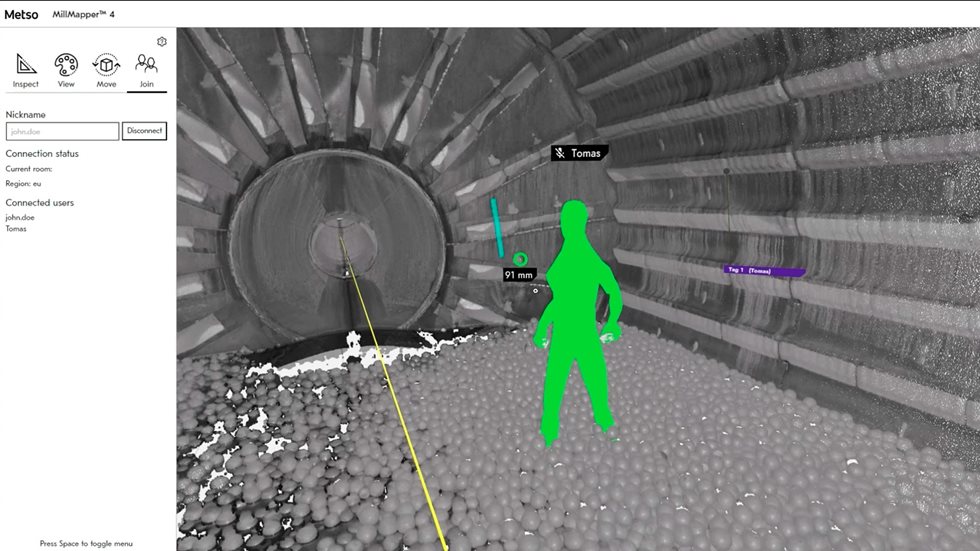

Metso MillMapper™ is a patented solution that captures over 40 million thickness points per scan, offering unmatched accuracy in wear analysis. It helps maintenance and operational teams understand wear behavior and it also helps Metso to optimize liner design, improve mill performance and to offer better products and service to our customers. Metso’s latest addition to the MillMapper suite is MillMapper 3D view, where you can enter your mill virtually and get a 360 view of all your previous scans.

Metso MillMapper™ has long been the industry standard for mill liner condition monitoring and has allowed Metso's liner experts to help operators globally to plan maintenance, reduce downtime and in fact optimize the performance. With the latest MillMapper addition to the software, MillMapper™ 3D View, digital wear analysis is taken to a new level.

In this blog, Metso’s wear analysis expert will take a closer look at the importance of monitoring how your liners wear and how it can impact your grinding performance.