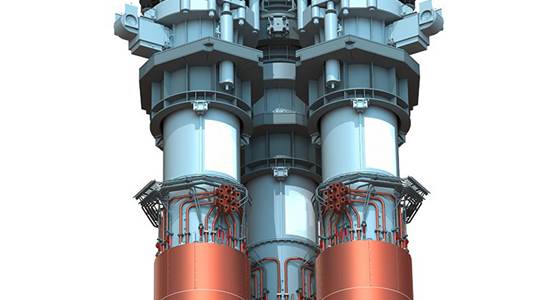

Ausmelt® TSL Furnace

- Flexible design tailored to meet specific requirements of the process & project

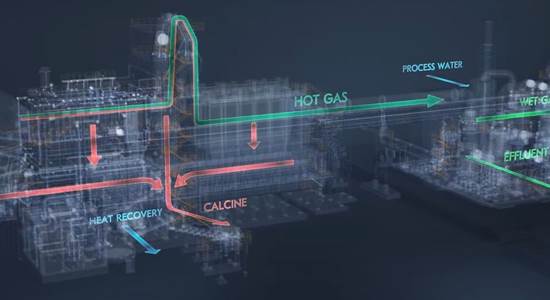

- Stationary furnace with effective sealing and operation under negative pressure to minimize fugitive gas and dust emissions

- Vertical arrangement with small footprint suitable for sites with limited space

- Range of molten product handling configurations enabling continuous or batch operation

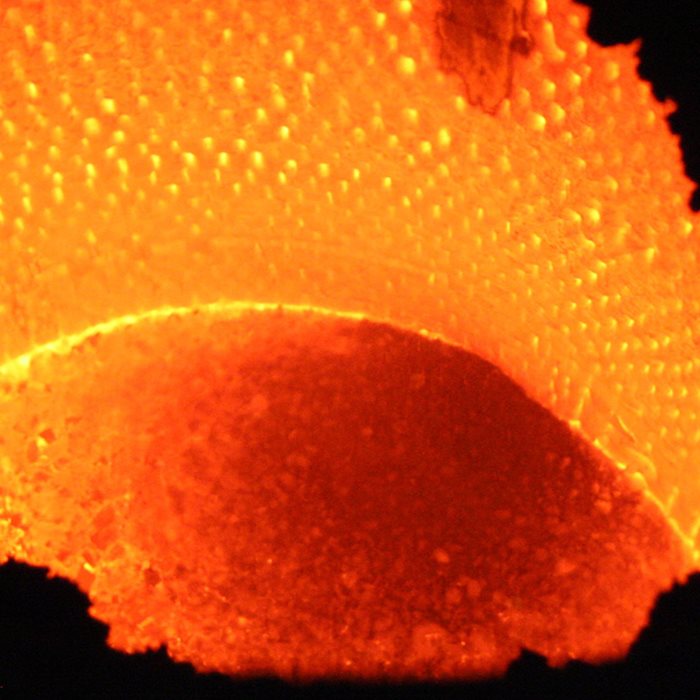

- Dedicated access points to facilitate faster, safer & lower-cost reline shutdowns

- Supported by digital and automation solutions to minimize operator interaction with plant and process