High metal recoveries

Energy efficient

Process flexibility & control

Substantial references globally

The Ausmelt TSL process has been applied across a wide range of non-ferrous smelting, converting, slag reduction and fuming applications. The technology is capable of operating at scales ranging from 200 kg/h up to more than 200 tph making it well suited for the recovery of not only base metals (Cu, Ni, Pb, Sn and Zn) but also critical minerals (Sb, In, Ge, Ga) and precious metals (Ag, Au, Pt, Pd).

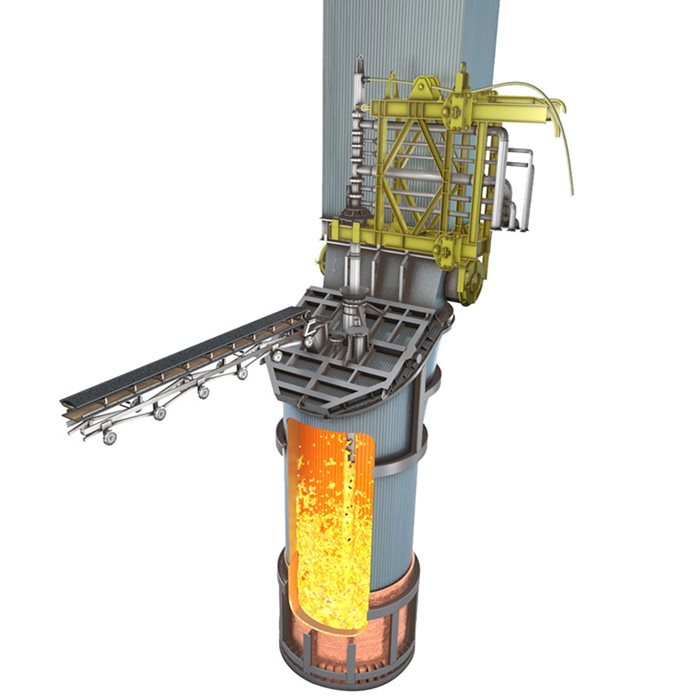

The Ausmelt process utilizes a vertical lance through which oxygen enriched air and fuel are introduced to the molten bath. Unlike other bath smelting technologies, fuel injection via the Ausmelt lance provides for independent bath temperature and oxygen potential (pO2) control, enabling improvements in metal recoveries and product quality control, particularly in reducing process applications.

- Possibility for co-treatment of primary and secondary feedstocks including concentrates, residues, slags, dusts, sludges, e-waste etc.

- Ability to handle significant variability in feed composition and physical characteristics

- Low dust generation rate (typically <1% of feed input)

- Precise control of operating temperature and bath oxygen potential for regulation of product composition and efficient removal of impurities

- Possibility for batch or continuous operation depending on capacity, product quality requirements etc.

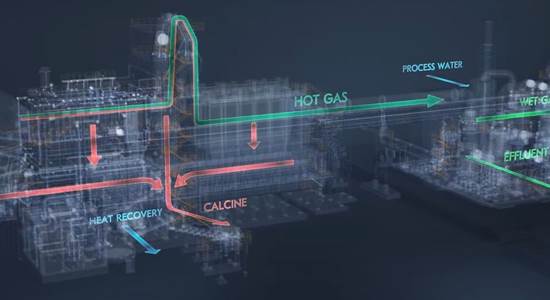

- High energy efficiency achieved through heat recovery to molten bath from the process offgas

- Highly automated process control for enhanced safety