Advanced technologies to convert the raw materials into Battery grade chemicals

Capability to support sustainable recycling and recovery of raw materials back to front-end of the battery value chain

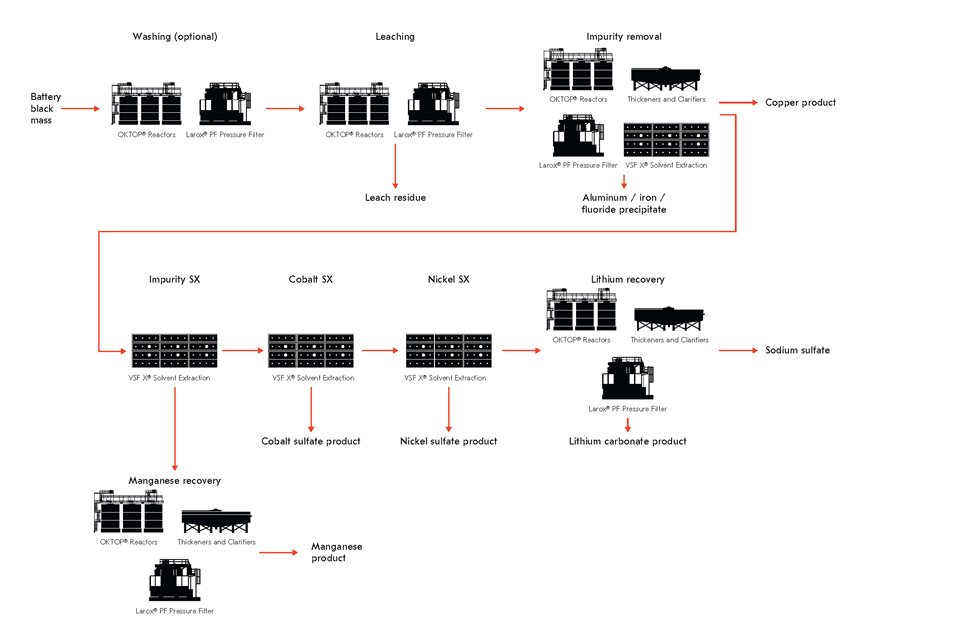

The flowsheet can be tailored according to the feed materials and desired end products

>60% reduction in embedded carbon

Key drivers for battery recycling industry

Battery black mass recycling is becoming increasingly important as a supplement to virgin material supply, as well as a way to reduce the carbon footprint of the battery supply chain.

With the increasing demand for zero emission vehicles and the need to create a circular economy, the battery recycling industry is inevitably set to see new and prosperous growth opportunities.

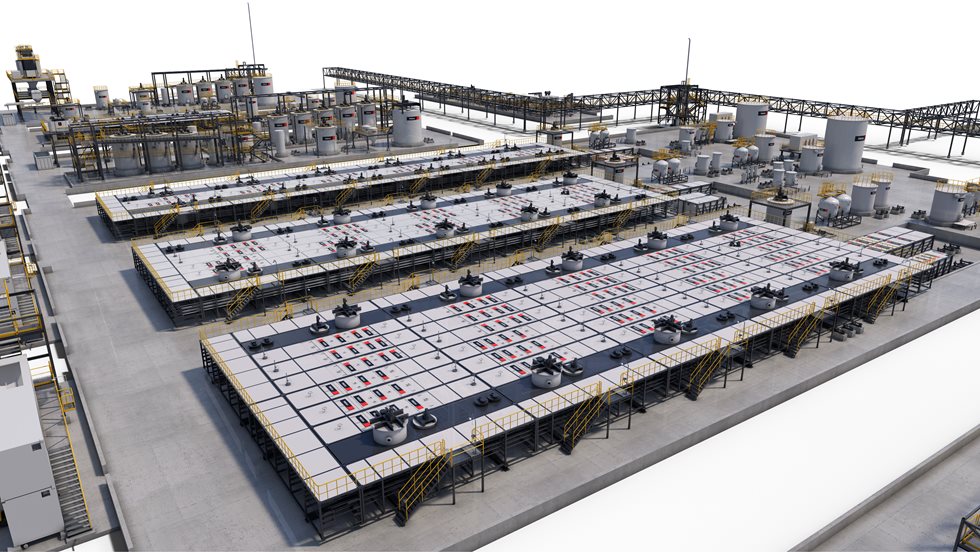

Introducing Battery Black Mass Recycling Process

Industry’s most comprehensive scope of supply

{{decodeHtmlEntities(field.label)}} |

|---|

Sustainable black mass recycling that helps our planet

Our biggest impact is through our customers when they use our technologies and services that help them to achieve their own sustainability and productivity targets.

Sustainable benefits with battery black mass recycling process:

- >60% reduction in embedded carbon

- >30% CO2 emissions

- >20% energy

- >20% water pollution

- >20% air pollution

The flowsheet contains Metso Plus core equipment such as:

- VSF® X Solvent Extraction Plant Unit

- Filters (Larox® PF filters, Dual Media (DM) filter, LSF filter)

- Thickeners

Battery black mass recycling process is compared with the production of virgin nickel sulfate, cobalt sulfate manganese dioxide and lithium carbonate.