Benefits

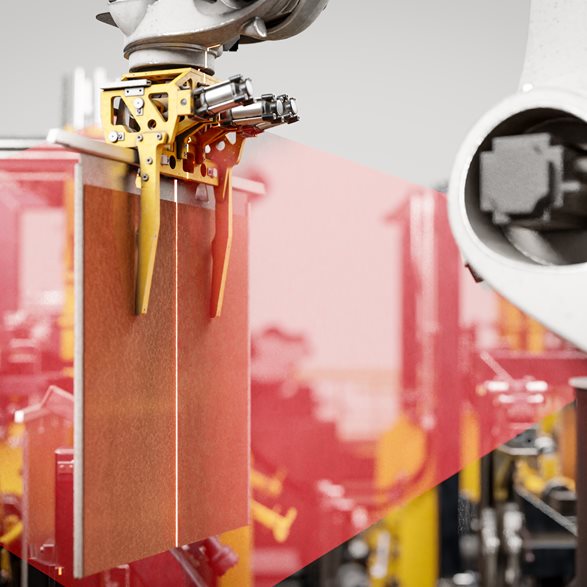

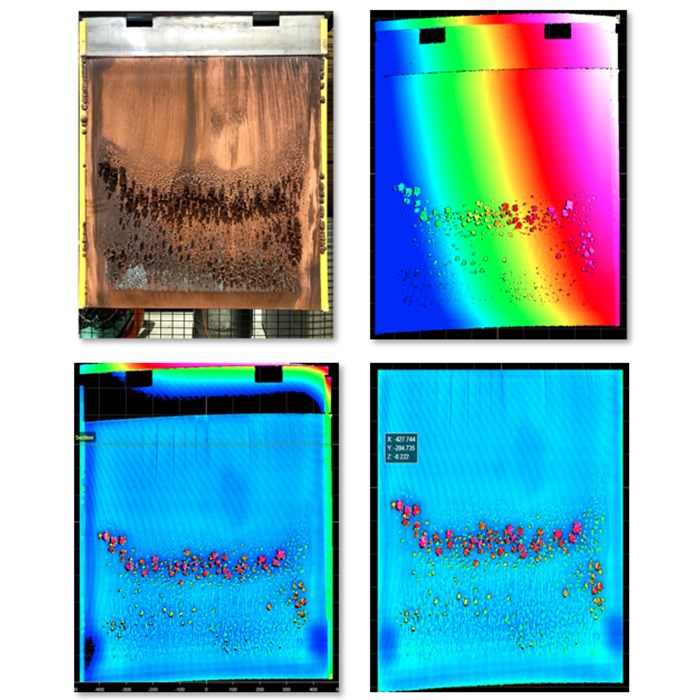

Copper surface scanning

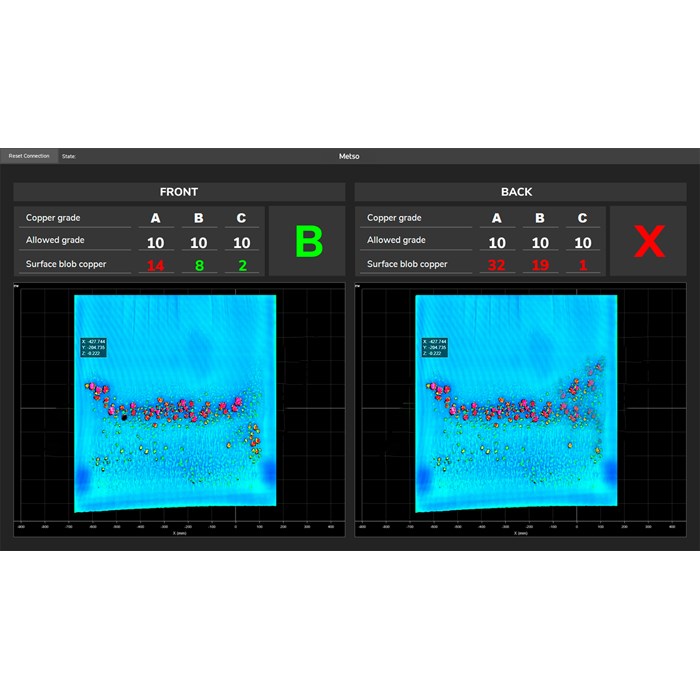

The final physical quality of cathode, including cathode condition, is inspected visually by different operators with shared duty of efficiently operating the machinery.

With customer requirements increasing towards a more systematic proof of cathode copper quality, it is of the utmost importance that we begin to utilize a more advance system approach.

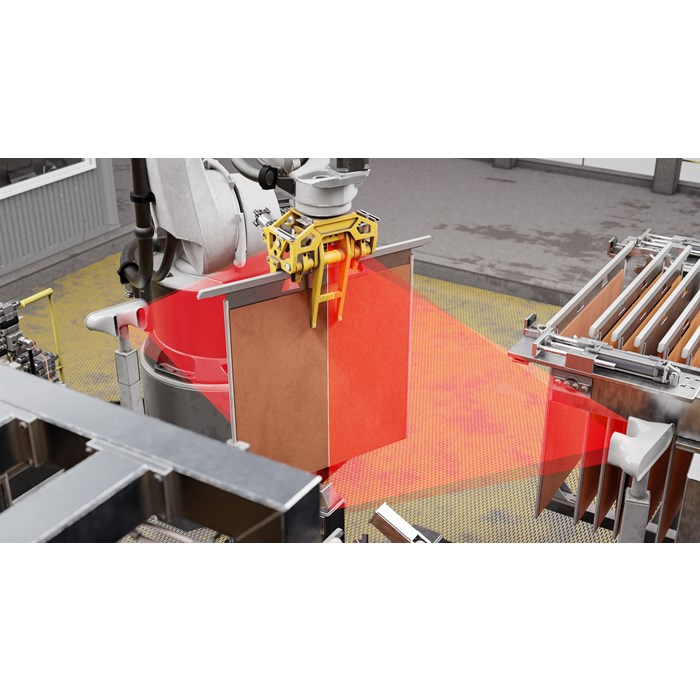

Introducing: CathodeSense+

- Continuous process improvement due to predictive quality management

- High resolution full 3D scan

- Adapted for all Metso CSM models and capacities

- Inspection time and result <1 second

- Designed for scannings with high speed robots

- Free standing equipment for simple integration with existing machinery

- Interface for implementation in different existing PLC systems

- Not dependent on external lightning equipment

- Systematical inspection of each cathode

- No calibration needed

- Enables automized defect categorization

- Metso has more than a 50-year track record in digital innovation

- Part of the Metso Sense series intelligent instruments portfolio which enables industry leading process optimization

- Proven and simple technology

- Well tested concept

- An improved and more robust version of CathodeSense

- User friendly user-interfaces

- Easy to implement in brownfield as well as greenfield

- Small installation footprint

- Free standing equipment with modular approach

- Enables simple interfacing with different control systems

- No calibration needed

- Fast Quality Analysis < 0.5 sec

- Capable to handle high-capacity throughput [600 cathodes per hour (c/h)]

- Works for all Cathode Stripping Machines (CSMs)

- High accuracy and reliable results on every cathode