- Minimizes plant downtime caused by unexpected failures

- Provides accurate information on equipment’s current condition and upcoming service needs

- Increases safety

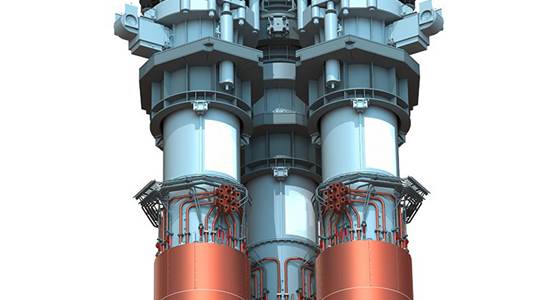

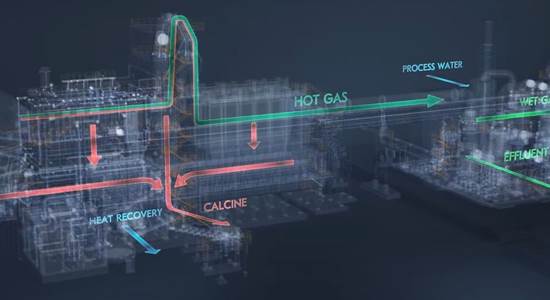

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

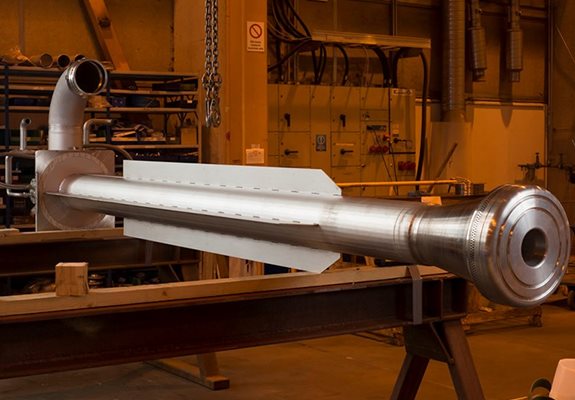

Maintenance of the CJD, which is part of the concentrate burner, is carried out at our workshop. It involves comprehensive maintenance procedures including also condition inspection of parts and the changing of spare parts within the agreed scope.

The final maintenance service report offers recommendations for repair and spare parts needs in the coming months. If there are larger components or assemblies that need to be refurbished, a refurbishment service can be added to the maintenance service. The service can also include a Metso specialist to supervise the installation of the CJD or to carry out a situation analysis at your site.