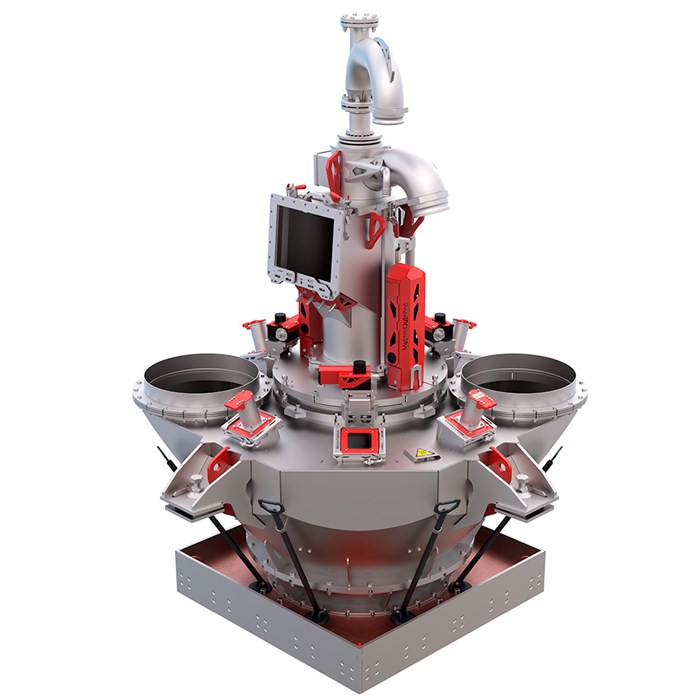

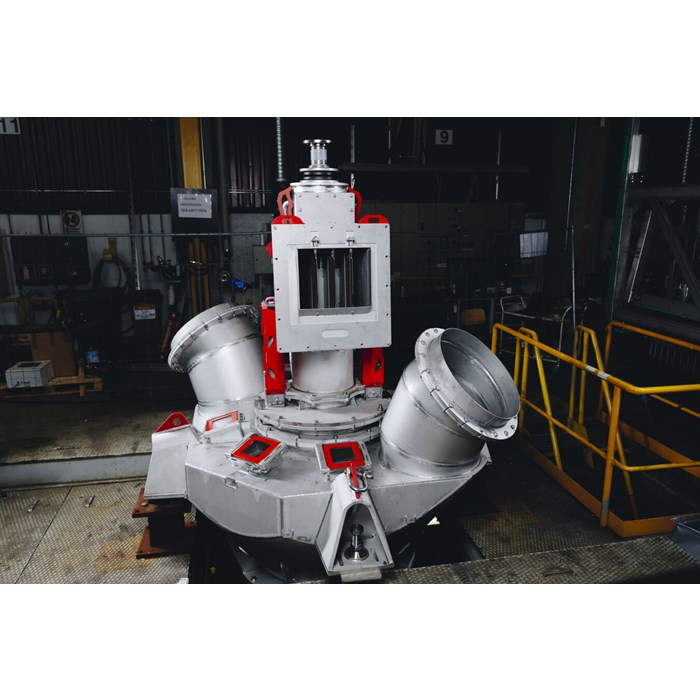

Metso's Outotec Octaburner is a sleeve-type concentrate burner with a central jet distributor structure. The burner design is a result of over half century of experience. It forms the heart of the Flash Smelting and Flash Converting process and lays the foundations for more sustainable metal production. Its operation can be adapted to meet the needs of different feed rates and feed analysis. Process parameters can be calculated using the Metso Process Advisor and operation controlled with advanced Metso Proscon Control System to enable significant improvements in furnace operation.

The Octaburner mixes the solids feed with oxygen-enriched process air to form a turbulent suspension, which ignites at the top of the reaction shaft. The rapid reactions that follow consume almost all the oxygen in the reaction shaft. The rigid construction maintains burner stability, while the sophisticated monitoring systems guarantee that high oxygen efficiency is maintained. Efficient operation is ensured with upstream Metso loss-in-weight feeders and air slides for accurate feed supply.

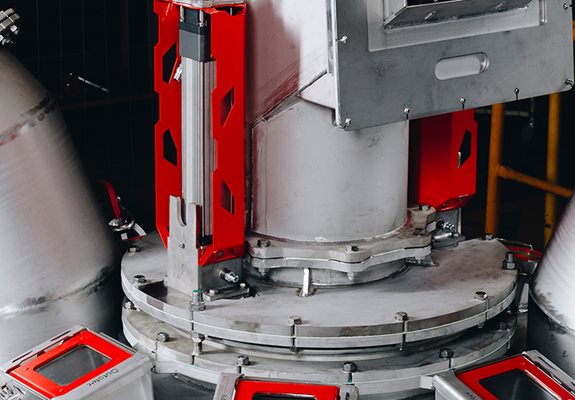

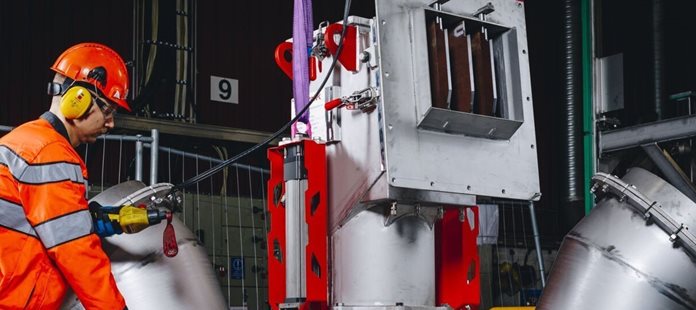

Metso's Outotec Octaburner’s improved design for solids feed and process air distribution further increases burner efficiency compared to the previous-generation Metso's Outotec Concentrate Burner. Process air velocity is accurately controlled using an integrated, low-maintenance system comprising two synchronizer linear actuators directly connected to the velocity-adjusting sleeve shafts and driven by servo motors. The lower height of the burner unit enables easy access for maintenance and adjustment, while feed inlet cleaning is easier thanks to a top-mounted hatch. The risk for blockages is reduced with a new type of feed division. The new air chamber design allows optimum integration of Metso's Outotec FlashGuard system for burner discharge monitoring during daily operation.