Metso OKTOP® Cooling Tower delivers high cooling performance with low environmental impact. Its patented horizontal outflow system ensures superior efficiency and significantly reduces emissions compared to traditional vertical-flow designs - making it a smarter, more sustainable choice.

Built from durable fiber-reinforced plastic (FRP) and high-grade stainless steel, these towers withstand harsh, acidic environments. With optional anti-scaling curtains and sizes of 2, 4, and 6 meters in diameter, they fit a wide range of process needs while maintaining proven reliability and environmental benefits.

Why choose 3rd generation OKTOP Cooling Towers?

Reducing top structure diameter from 10 to 6-meter leads to smaller footprint and allows a tighter layout

Equipped with automatized cleaning spray nozzles, ensuring the longest operational intervals in the market

The old design required 8 x 40-foot containers per tower, while the new design requires 6 x 40-foot containers per tower. Possibility to deliver equipment as complete to sites

The simpler structure and higher rate of pre-fabrication in the workshop reduce installation hours by 25 – 95% depending on installation scope and design

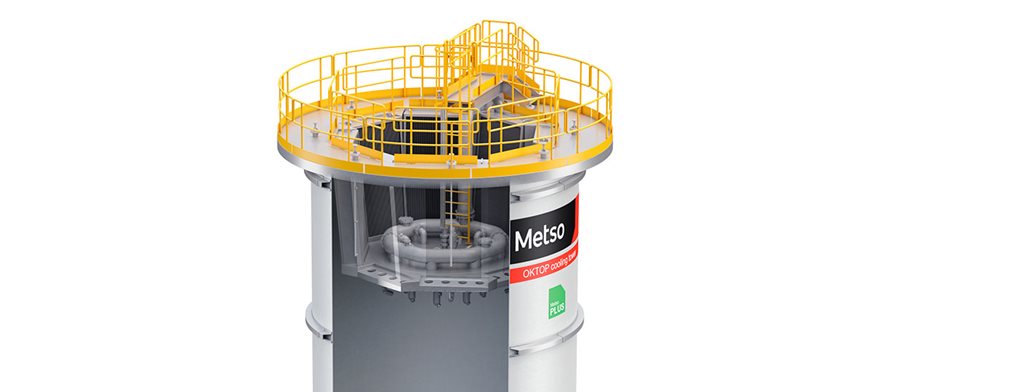

Metso has developed the 3rd generation OKTOP® Cooling Towers to address key customer challenges in demanding industrial environments. This new OKTOP® Cooling Tower builds on a well-established foundation, utilizing the same horizontal outflow demister ideology as the previous design.

The OKTOP® Cooling Tower is designed for maximum efficiency within a minimal footprint. Its compact layout allows for a one-to-one replacement of conventional cooling towers while doubling cooling capacity. With a foundation design that requires minimal construction and a low overall footprint, this solution delivers high capacity without compromising space or performance.

Designed with uptime and simplicity in mind, the OKTOP® Cooling Tower features advanced self-cleaning technology and maintenance-driven solutions.

3rd generation: main features

- The new 3rd generation Cooling Tower enables advanced cleaning methods for improved reliability

- World’s first self-cleaning cooling tower (patent pending)

- Retractable central cleaning tool reaches all surfaces below droplet separators

- Automatic valve protection keeps cleaning nozzles secure during operation

- Eliminates need for anti-scaling curtain (optional if required)

- Dedicated spray nozzles allow interval cleaning of each droplet separator

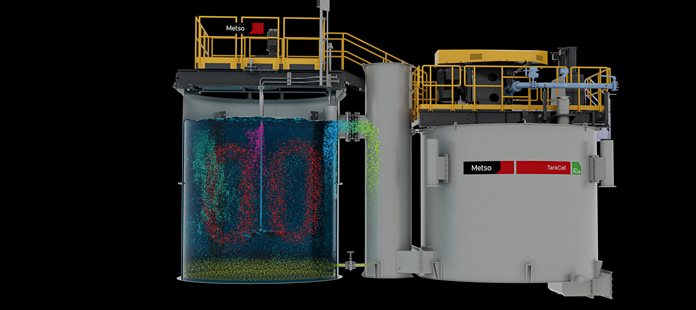

Metso OKTOP® Cooling Tower provides efficient and sustainable cooling, controls emissions effectively and uses innovative maintenance procedures. The heart of OKTOP® Cooling Towers lies in their patented horizontal outflow system. This innovative design ensures efficient cooling while minimizing emissions. Compared to conventional vertical-flow demisters, the horizontal-flow demisters significantly reduce environmental impact.

Operation

2nd generation: main features

Related services

Downloads

If downloading does not start automatically, click the link below.