1200+ rotary kiln installations

Metso's R&D Center supports optimum process design and

equipment layout

120+ years of experience and process know-how

Experience applying kiln technology to various materials:

Coke, Lithium, and more

Designed to make a difference

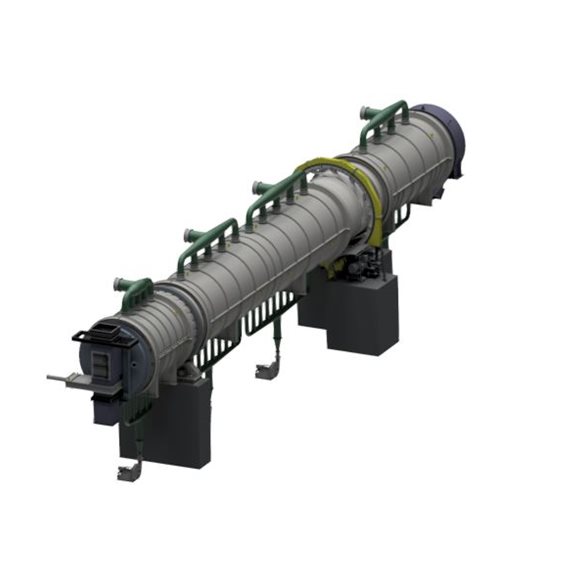

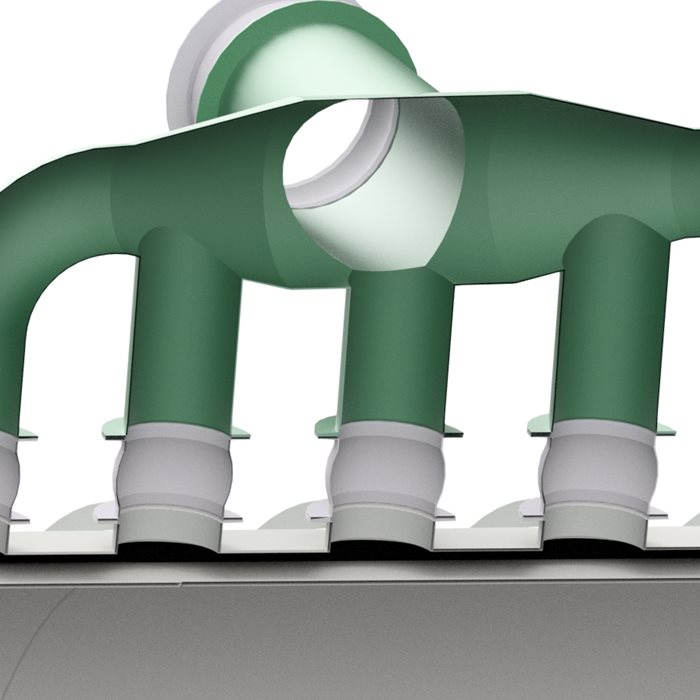

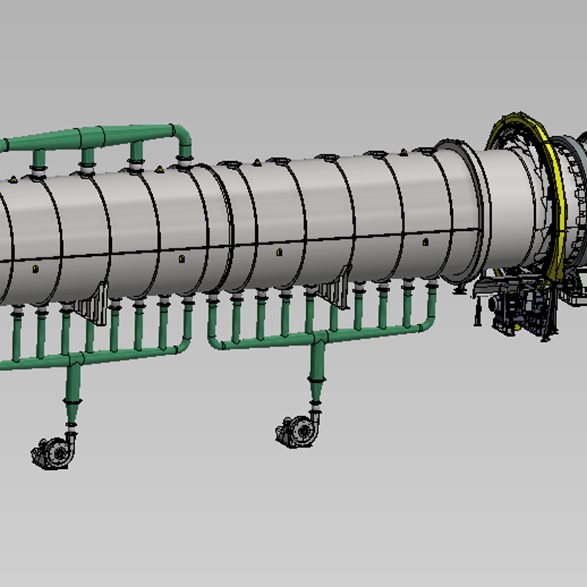

Metso’s Cross Flow Rotary Cooler is an innovative solution designed specifically to decrease water consumption and improve energy-efficiency in pyro processing plants. It boasts of a simplified cooler shroud design that reduces overall plant water consumption and is suitable for special applications such as oxidation, fouling or scaling.

It utilizes the indirect heat exchange principle, where heat is transferred into a secondary air stream. The recovered heat can be used in other plant processes and thus, decrease the carbon footprint and enhance sustainability of process plants.

- Savings in water consumption and capex for water cooling circuit

- Heat recovery and improved plant energy balance

- Hybrid design, allowing for improved temperature control at both nominal and design cases

- 35% lighter shrouds than waterfilm shrouds

Decreasing capex, opex and water consumption

Sustainable technology for a greener future

The global market has identified decarbonization of both industry and society as an essential focus area. There is a tremendous rising demand for electric vehicles, energy storage systems and more. At Metso, we are developing greener technologies with lower carbon footprint to efficiently produce high-grade materials for these technologies and emerging feedstocks.

To process these materials, there are several different process routes available or under development. The selection of the process route and main equipment determines not only the initial investment cost, but also the operational cost and product yields. Metso’s cooling technologies are designed to lower plant-wide operational costs to increase the competitiveness of our customers’ plants.