Cu POX – High-efficiency leaching solution

(>98.5%) for maximum yield

Lower emissions and closed-loop water recycling

Optimal temperature and oxygen pressure

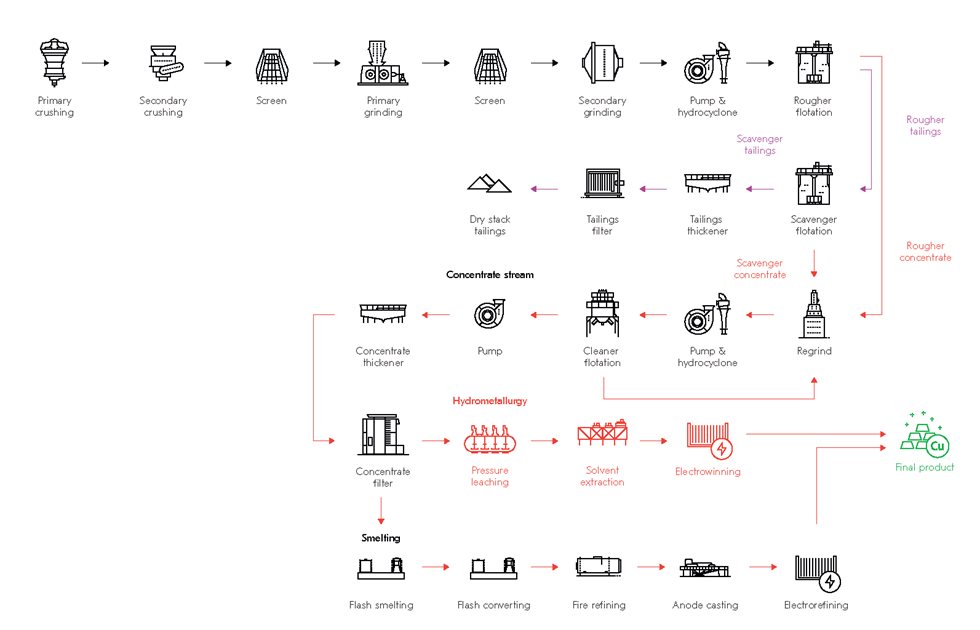

As a standard process solution Cu POX is implemented with SX-EW facilities to produce high quality cathodes,

but Cu POX can also be utilized to refine low grade copper concentrates to produce substitute PLS for existing SX-EW plants to compensate depleting heap leaching.

Process flow: Cu POX - SX - EW

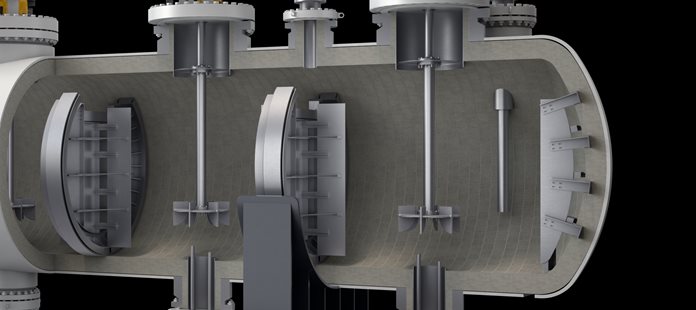

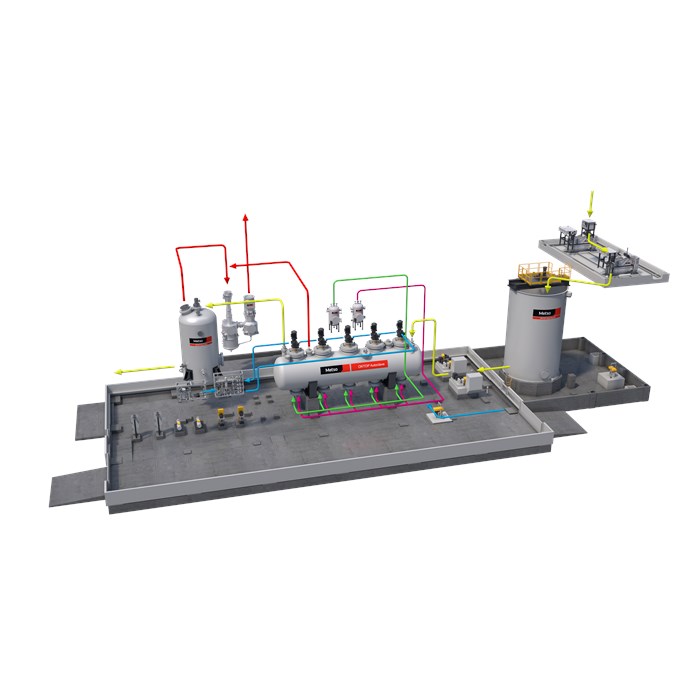

At the heart of Cu POX technology is the OKTOP® Autoclave unit. Oktop Autoclave ensures high availability offering pre-designed, compact plant footprint, reliable performance, effective metal recovery and robust proprietary equipment for a comprehensive plant unit delivery with guaranteed process performance.. This unit includes:

- Feed tank / reactor

- Autoclave

- AC Agitators with seals supply loop

- Flash tank

- Level control valve, pressure let-down valve

- Blowback tanks

- Scrubber

- Instrumentation and automation

- Autoclave Feed Pump*

- Isolation valves*

- Blast spools*

- Pressure piping*

* Third party partner

- High copper recovery

- Closed loop process steps reducing the use of water

- Tailored integration with SX/EW plant

- Reduce investment risk, one stop shop technology provider

- Full value chain knowhow from ore to copper metal

- Guaranteed process performance