CycloneSenseTM brings smart monitoring through combined visualization and measurement.

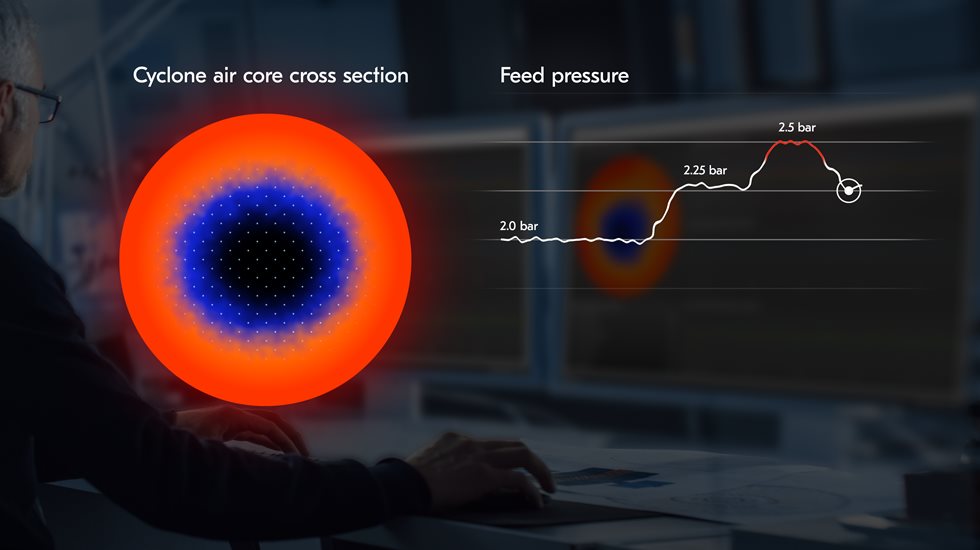

CycloneSenseTM visualizes the hydrocyclones air core through direct measurement and allows you to see the points where roping and other issues are experienced. The continuous and direct measurement provided by CycloneSenseTM enables an automatic cyclone control with real-time analysis. This information helps in finding the optimal operating point for hydrocyclones by controlling variables such as feed pressure, density, and the number of operating cyclones.

- Direct, continuous and robust online measurement of hydrocyclone air core

- Turns a hydrocyclone into a smart and connected asset

- Identifies problem situations

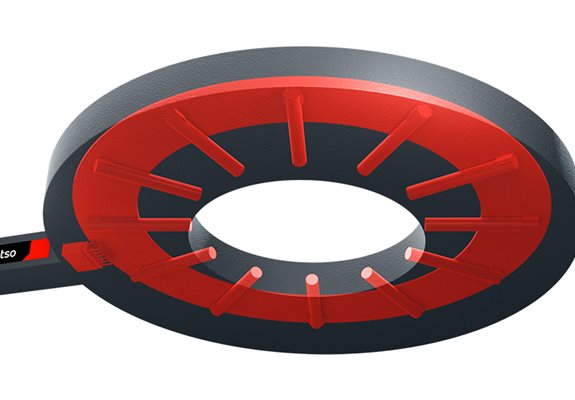

- Based on process tomography technology

CycloneSenseTM provides valuable input for optimization of grinding circuits and hydrocyclone performance. Data from CycloneSenseTM can be used to ensure that the hydrocyclones operate at an optimal operating point, identify problem situations and enable preventative actions.

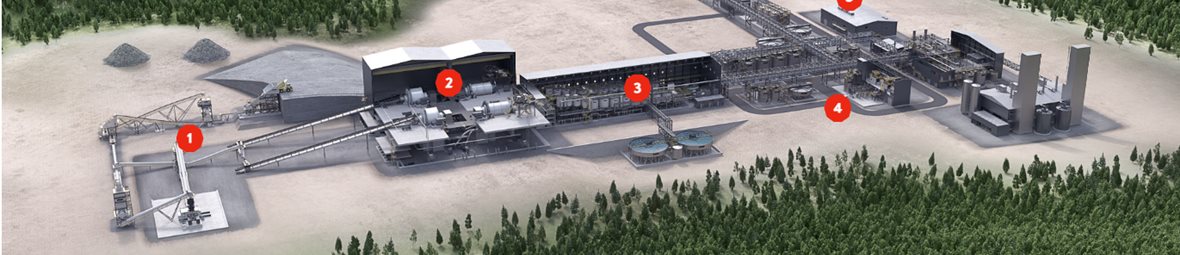

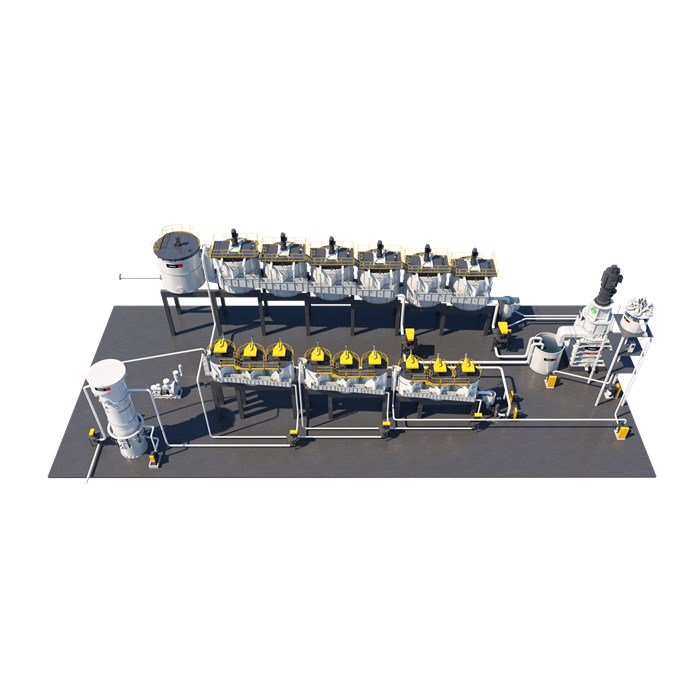

When the CycloneSenseTM is integrated with a particle size measurement from the combined overflow stream (PSI® 300 or PSI® 500) it enables maximizing process uptime while achieving optimal particle size distribution, which results in optimal recovery in flotation and less downtime due to sanding, roping or blockages.

- Increases uptime and production

- Identifies optimal operating point for hydrocyclone

- Enables optimization of grinding and flotation circuits

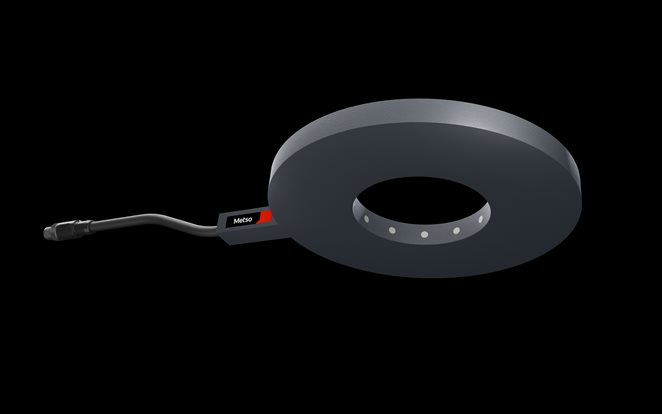

CycloneSenseTM is available for all new Metso hydrocyclones and it can be installed on already existing Metso or other manufacturer hydrocyclones. The gasket is installed between the lower and upper cones and is easy to change at the time of relining of hydrocyclones. CycloneSenseTM is easy to install, operate and maintain with no moving parts.

CycloneSenseTM is delivered as a ready-to-install package.