Unique know-how and leading digital technology to help you reach your sustainability targets

Advanced electromagnetic scanning technology

Up to 60% less downtime due to quicker inspections

Every flaw is detected with high resolution scans

Detect problems and prevent failures with proactive maintenance

Benefits

- Safer and up to 60% quicker inspections

- Gain maintenance insights and prevent problems

- Increased detection capabilities over a large area

- Condition data available for asset life cycle analysis

- Easily identify root cause of issues

Scanning process

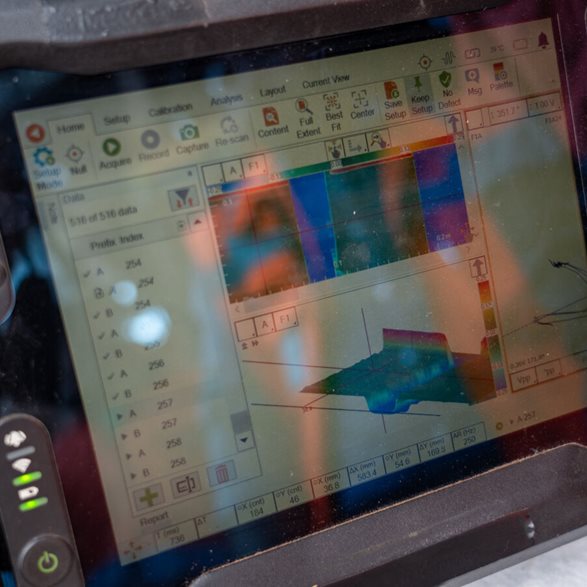

Digital gear inspections utilize advanced electromagnetic technology to scan and record the gear tooth condition faster and with more accuracy than any other method available.

100% of a vast area is covered within a single scan producing a digital footprint in high resolution to achieve accurate data on every defect of the girth gear with minimal valuable downtime.

Inspections are simpler and safer for hard-to-reach areas which is a major improvement from conventional methods.

The scan patterns are analyzed to create a digital report providing insight for the maintenance team and accurate component replacement forecasts.

Scans are automatically recorded and saved for future trending, comparisons and analysis. No consumables are required for the inspection and less preparation for test material is needed.

Inspection deliverables

- Conduct a non-destructive electromagnetic examination using ASTM-E2905

- Detect flaws in high resolution

- Collect data

- Identify the root cause of issues

- Digital report of findings

- Remedial repair recommendations

- Conduct a failure analysis including their severity and impacts on the operational function of the gear as per AGMA 1010

- Component replacement forecast

Digital girth gear inspection video