Metso’s Outotec® pilot DRI Smelting Furnace

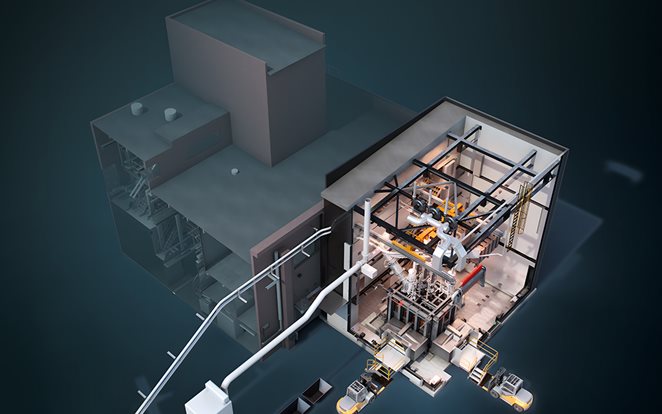

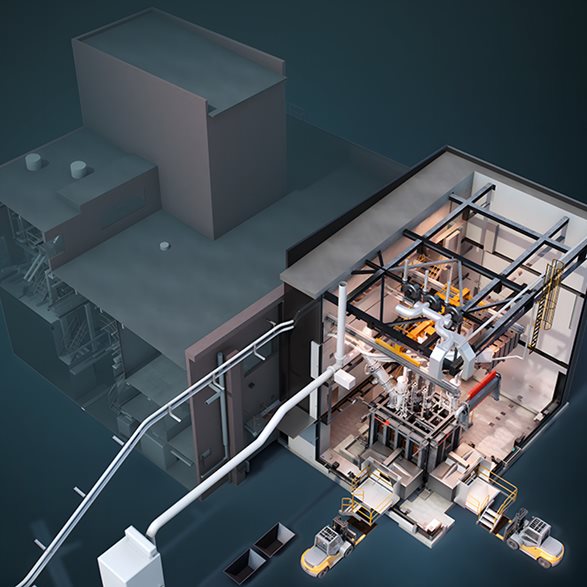

Pilot smelting furnace is designed for direct reduced iron (DRI) smelting, demonstrating equipment and process features of the large industrial scale Metso´s Outotec® DRI Smelting Furnace. It serves customers together with circular AC and DC electric furnaces located in Metso Research Center in Pori, Finland.

Since DRI properties are varying based on iron ore body and direct reduction technology used, piloting tests before industrial scale investment are very useful to validate simulation data and to verify the feasibility of the customer project. Differences can be seen for instance in DRI iron content, impurity contents, metallization rate and carbon content.

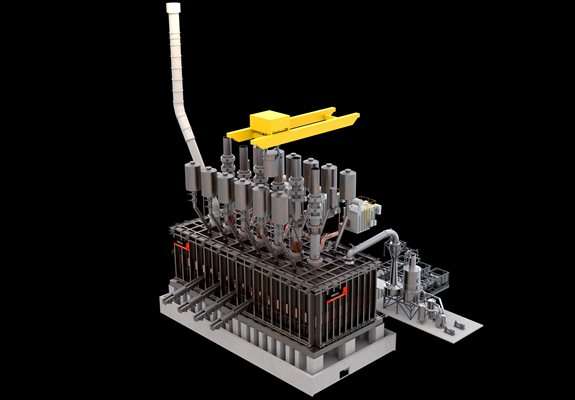

DRI pilot smelting furnace has three electrodes in line configuration. It is equipped with 2.5 MVA transformer allowing demonstration of DRI smelting in a scale of ~1 ton per hour. For typical one week test campaign about 50 tons of test material is required.

Details:

- “3-electrodes-in-line” rectangular smelting furnace with 3-dimensional binding system.

- Feeding arrangements for four separate materials.

- 2.5 MVA transformer.

- 200mm graphite electrodes.

- Metso Proscon process automation

- Separate tapping arrangements for hot metal and slag.

- Hearth dimensions 1.8m x 2.8m.

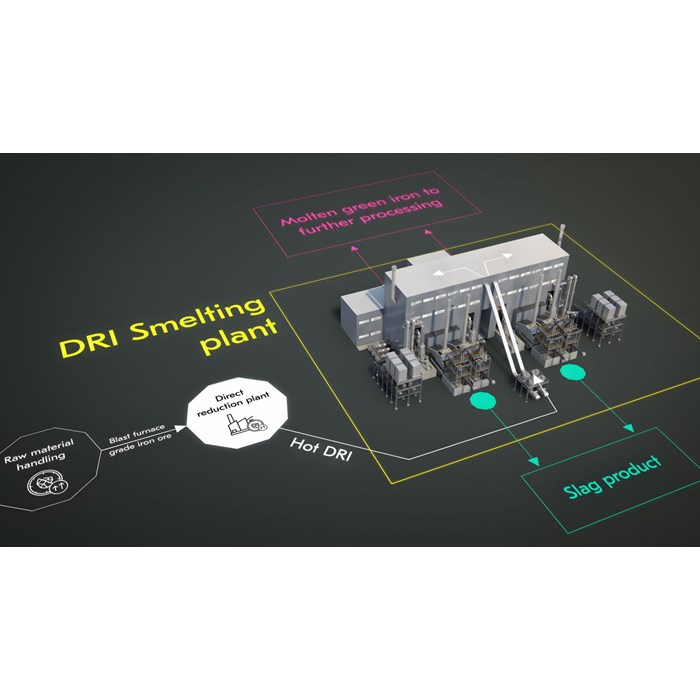

- High capacity 6-in-line DRI Smelting Furnace to replace blast furnaces (BF).

- Can use direct reduced iron (DRI) made from BF - grade iron ore by enabling high slag volumes.

- Can be implemented next to existing BF for minimal production losses and a significant reduction in CO2 emissions with no changes needed to the rest of the steel plant.

- An optimal solution based on proven technology for large-scale DRI smelting applications.

- Metso's extensive R&D capabilities have enabled filing of multiple patent applications.

Metso’s Outotec DRI Smelting Furnace provides the following benefits:

- Flexible for any DRI feed

- High productivity with capacity above 1.2 million tons per year

- Continuous production of hot metal with high availability and long campaign life

- Capable of handling large slag volumes

- Possibility to change slag chemistry to achieve high iron yields and good-quality slag

- Minimal changes to existing steel plants and steel grades

- Furnace off-gas can be used as energy or in a carbon capture and storage process