- Decreased maintenance costs

- Longer lifetime

- Improved reliability

- Increased availability

- Minimized power waste

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

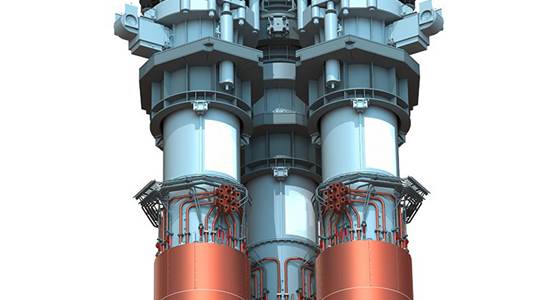

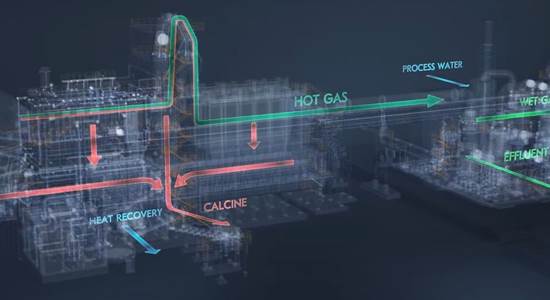

A WESP is traditionally the last piece of gas cleaning equipment before the process gas enters the acid plant or stack. Performance losses in this section can have a significant influence on acid product quality, plant availability or maintenance costs as passing particles will lead to impurities in the sulfuric acid, form plant deposits or result in emissions into the atmosphere.

Ensuring high performance of the WESP is therefore essential and requires in-depth knowledge of the equipment with regards to process, mechanical and electrical aspects. Due to long service intervals, it is almost impossible to develop and maintain this expertise with site personnel. Failing to provide the appropriate equipment care can have a negative influence over time and lead to:

The Metso EDITUBE WESP inspection scope combines three areas of expertise into one comprehensive service package, ensuring the maximized performance of EDITUBE throughout the lifetime.

The inspection consists of reviewing the current WESP operation, inspections of the mechanical and electrical conditions including:

These activities are performed by experienced Metso service personnel while maintaining the highest standards in work safety.

A service report is compiled for each inspection which summarizes the overall condition of EDITUBE and provides recommendations for improving operations, alignment and follow-up maintenance, which may include repairs or replacements. Possible upgrades and modernizations are recommended and the spare part status is verified.

The regular performance of the WESP inspection supports a systematical approach to plant maintenance and provides benefits for the plant operation such as: