Unique know-how and leading process tools to help you reach your sustainability targets

Understand your flotation process and current production performance

Identify areas of improvement with performance benchmarking

Evaluate disturbances, changing the feed ore type or changing the reagent addition rates

Obtain a recommended upgrade path with ROI calculations

- In-depth analysis and status of current production performance

- Performance benchmarking against similar global operations

- Identification of potential areas for improvements

- Recommended upgrade path with ROI calculations

Lost recovery in the flotation circuit results in lost revenue

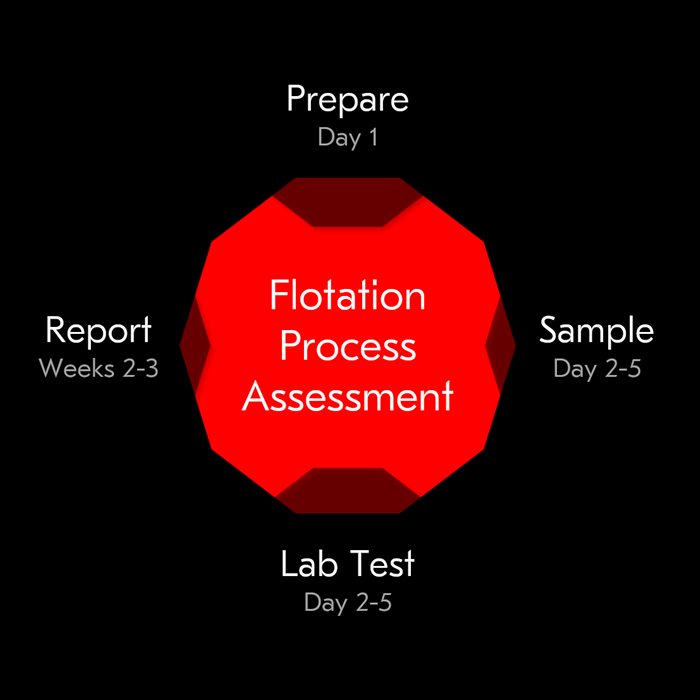

STEP 1: PREPARATION OR ANALYSIS OF EXISTING STATISTICAL PLANT DATA INCLUDING:

- Recovery

- Grinding performance

- Reagent doses

- Operational parameters

- Mineral characteristics

STEP 2: SAMPLING

- Sampling is conducted on a focused flotation area

- Samples are taken from the feed, tails, and concentrate

- Process conditions are monitored in the control room

STEP 3: HOT LAB FLOTATION TEST

- Hot flotation tests identify the potential of current ore

- Metallurgical performance in the laboratory and plant are compared and further analyzed using our HSC chemistry software

STEP 4: REPORTING:

- A report recommended solution, and value-adding process modifications are provided by our metallurgical experts