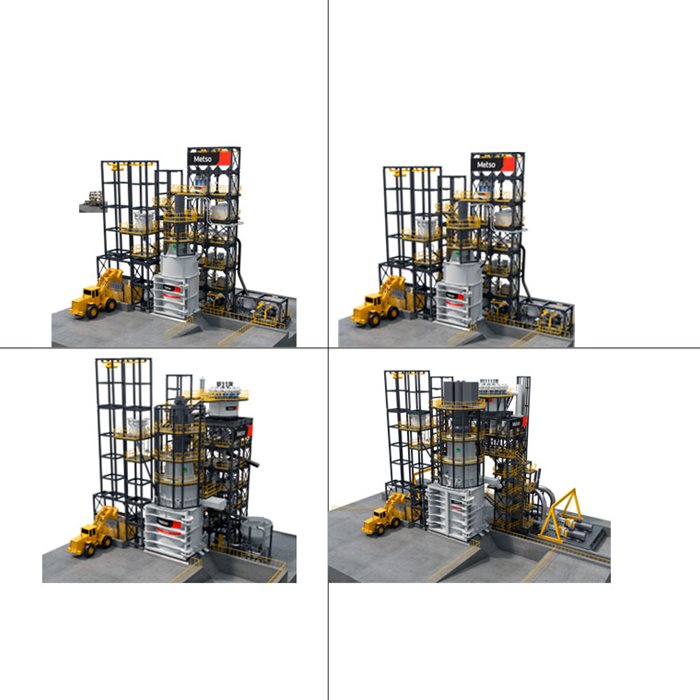

Reduces installation duration by up to 400%

Reduces installation cost by 25% due to reduced site duration and smaller crew size

The pre-engineered solution is trial assembled and tested in the factory to eliminate potential error

Safety is embedded in the design and is validated in pre-assembly

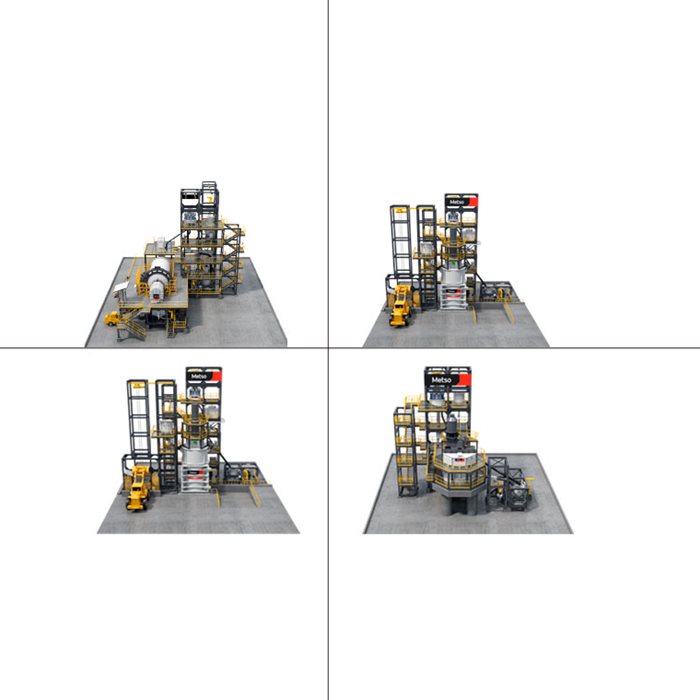

Pre-engineered, modular solutions

Our grinding solutions are designed to efficiently target coarse particle reduction while enabling flexibile configuration with the various particle classification hydrocyclone across all mill types. We focus on seamless integration of slurry handling, classification, and online particle analysis to optimize system performance. With built-in design flexibility and scalable scope, our approach ensures adaptability to your operational needs.

Our pre-engineered steel frames are built to ISO containerized standards, meeting both transport and operational requirements. Safety is planned into every stage of the lifecycle—from installation to operation and maintenance. In our factory, we pre-assemble slurry hoses, utility piping, cable trays, hose racks, lighting, monorails, grating, handrails, and equipment wherever possible, ensuring faster deployment and reduced site work.

Using hydrocylone is common in seperating coarse particles for further grinding effort, our pre-engineering module enables the scale of scope in different mill type and even multiple classification stages.