Why upgrade your grinding mill?

Upgrades provide additional safety for crew

Upgrades help you ramp up capacity

Upgrades help to increase equipment life

Upgrades help to simplify and speed up maintenance

Incorporating modern technology without major investment

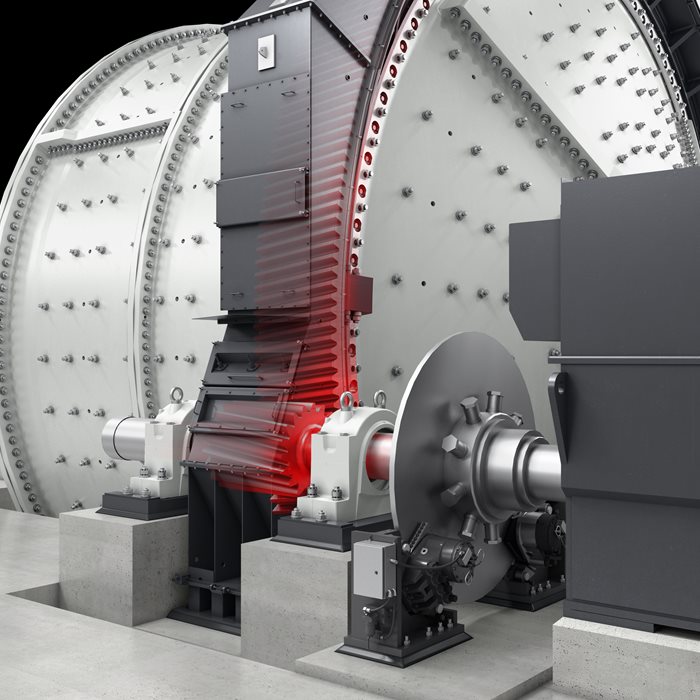

Gear and pinion operating conditions affect your system profile temperature, and proper pinion temperature control can mean the difference between a healthy asset lifecycle and damaging loss.

Improve operating safety and prevent unsafe working conditions with Metso’s pinion temperature monitoring system. The system replaces labor-intensive manual gear set temperature readings and provides real-time operating data as a valuable calculator of critical operating factors such as gear set alignment and lubrication.

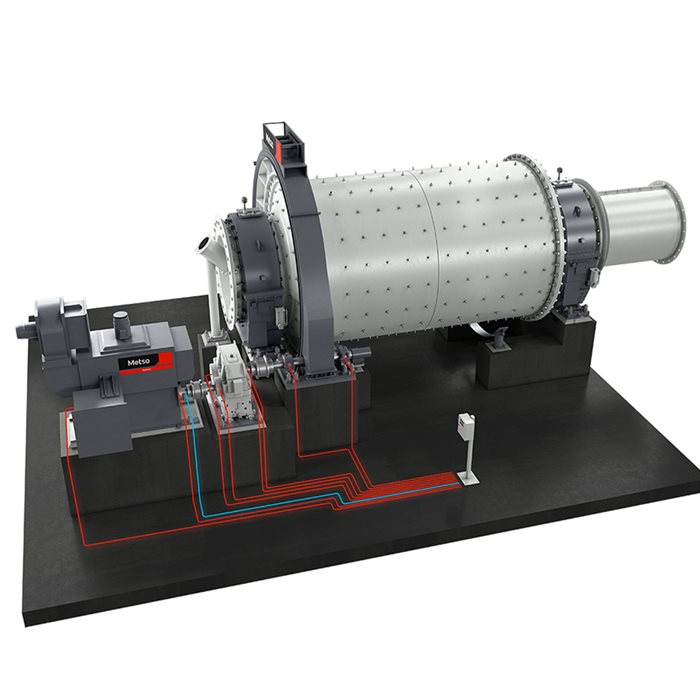

Ball mill feed spouts experience constant wear and need to be changed periodically to allow ongoing operation. Our ball mill feed spout design allows you to optimize the feed spout to align with your maintenance plan by combining a range of lining materials, sealing solutions and sensors to provide a complete feed end solution. Improved ball mill feed end design maximizes mill availability while minimizing feed end leakages and material waste.

Knowing the condition of your grinding mill equipment allows you to plan maintenance and operations more effectively. Metso’s vibration monitoring system detects existing and developing mill drive train issues to allow you to plan preventative maintenance activities during planned shutdowns. The system helps to monitor the health and maximize the reliability of your grinding mill and eliminate critical machine component damage.

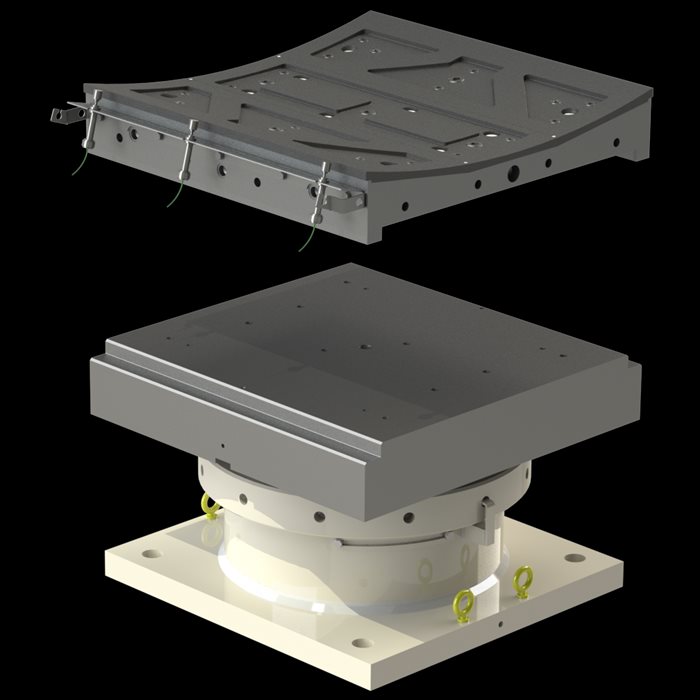

Traditional bearing pads with accumulator circuits comprised of a lube unit, gauges, and nitrogen tanks take up a large footprint and often cause downtime due to maintenance requirements or failure.

Metso polymer pads use advanced material technology to deliver long-lasting performance extending the operating life and improve the bearings' reliability in bearing-supported horizontal mills.

The pad design and the elastic properties of the polymer also ensure that an adequate film of oil is maintained throughout the mill operation.

The lubrication system is more efficient, as no accumulator circuit is required, which reduces space requirements, maintenance needs and improves safety.

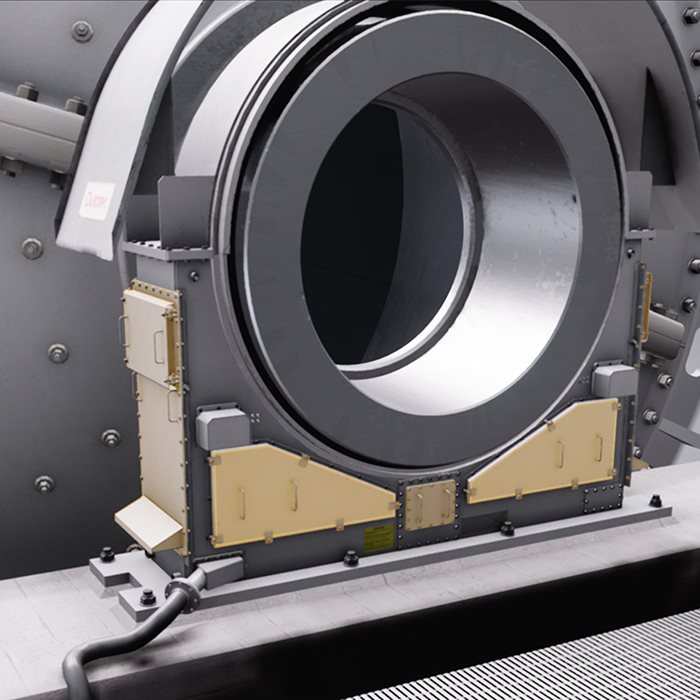

Contamination, extreme heat, and insufficient lubrication all pose risks to your gears and pinions. If not prevented, these will cause accelerated wear and decreased operating life.

Ensure the health and longevity of your gears with a gear guard upgrade. This includes support columns for safer maintenance, a gear spray system for optimal lubrication, infrared monitoring to track health, and a pressured and sealed system to prevent contamination.

Download the leaflet > - Opens in a new window

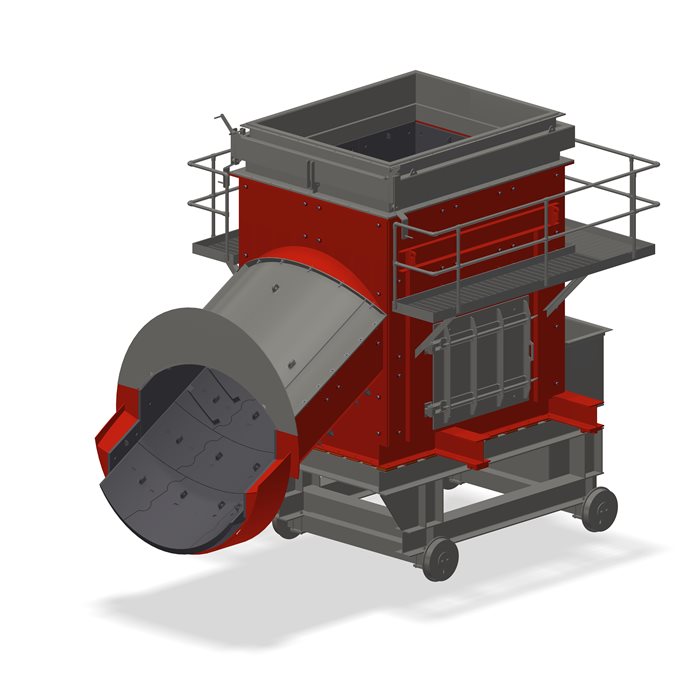

A feed chute design that adds safety while improving serviceability and functionality at the same time. Our design features are proven to address the typical issues with feed chutes that often disrupt our customer's business.

Reduce downtime, improve safety and simplify access.

Features include:

- Rock-box design (shown here)

- Removable chute cover

- Liner upgrades

- Inflatable and labyrinth seals

- Access platform

- Access hatch

- Carriage and trolley alignment upgrades

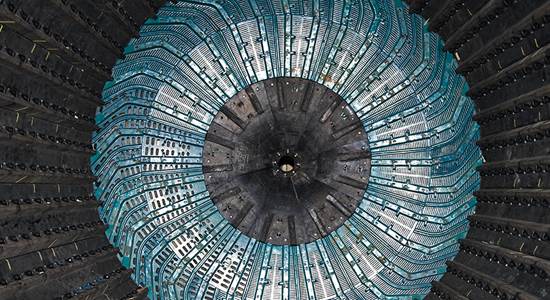

The Metso slurry wheel upgrade is a retrofit sealing solution for the grinding mill feed end. The existing configuration is replaced with a new and improved slurry return system featuring a unique water-wheel design that significantly improves the material containment of the feed ends. More effective sealing helps to prevent excessive slurry spillage and reduces premature seal wear and its associated costs.

Our trunnion liner upgrade replaces the existing single piece feed and discharge end trunnion liners with a two-piece design. The new design has proven to improve trunnion liner reliability, durability, and maintainability of the mill trunnion linings and bearings.

The main lining acts as a sleeve insert that is secured in the trunnion by a retaining ring. Dividing the trunnion liner into two pieces enables better distribution of the loading conditions. The improved load conditions reduce stress on the trunnion and fasteners to extend product durability and optimizes wear components.

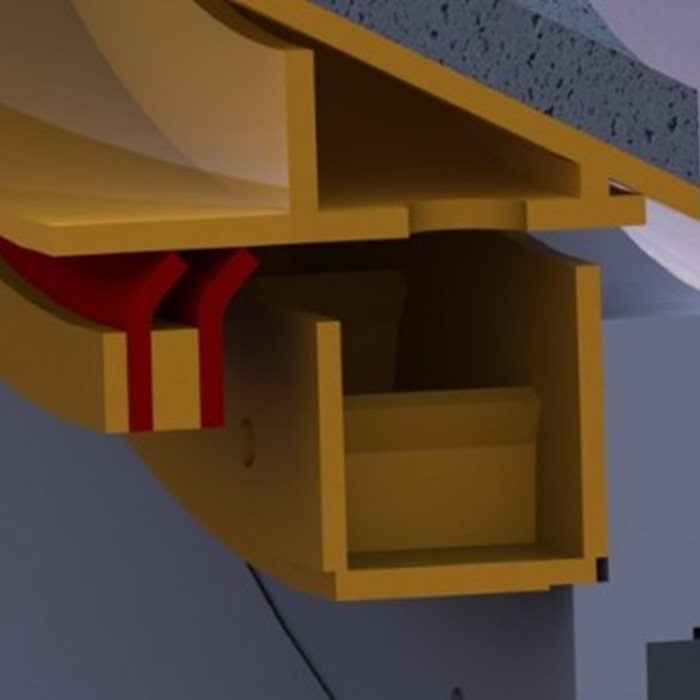

Oil leakage from trunnion bearing seals can cause many environmental and administrative concerns. The Metso barricade seal arrangement solves the myriad of issues around the proper sealing of grinding mill main bearings. Our design incorporates protective properties superior to any arrangement yet brought to market. The barricade arrangement is now standard supply for all new Metso mill installations and can be retrofitted to many existing mills.

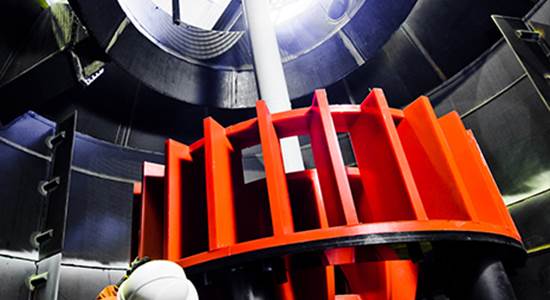

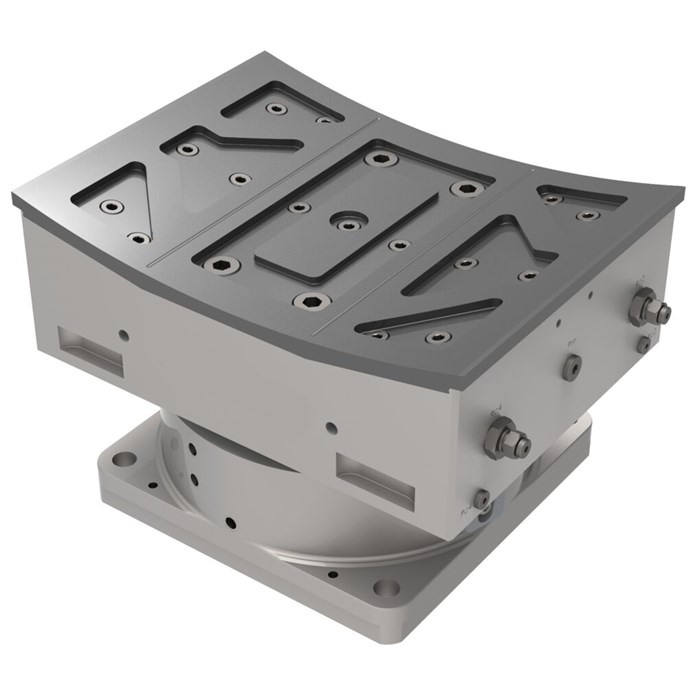

The Metso HSB upgrade is a modernization solution that helps maintain the optimal performance of grinding mill equipment. The proven design improves the durability and serviceability of both radial and axial hydrostatic bearing pads and is the standard arrangement in many new mill installations.

Existing bronze bearing pads are replaced with pads made from an advanced compound that significantly improves the maintenance, reliability, and longevity of both radial and axial pads. The upgrade solution helps reduce lost production time due to bearing-pad surface damage and decreases operational and maintenance costs.