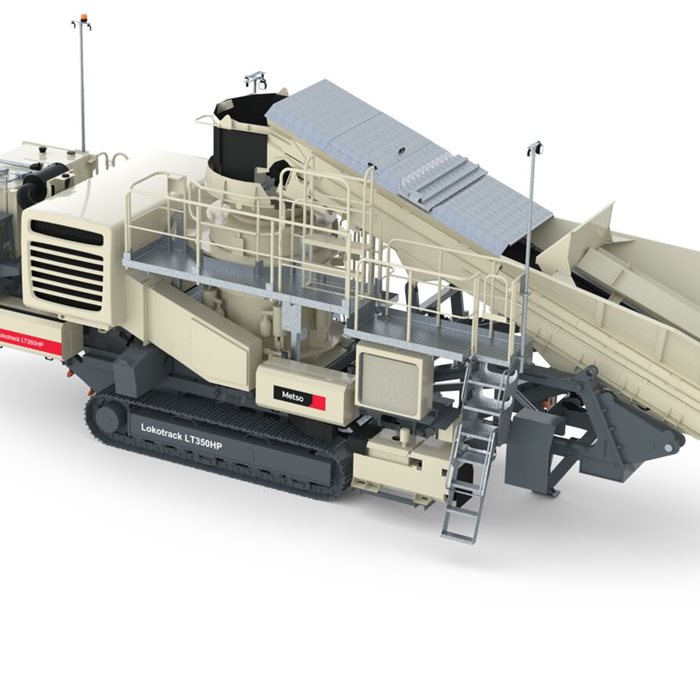

The Metso Lokotrack® LT350HP™ mobile cone crusher features the Nordberg® HP350e - Opens in a new window cone crusher, delivering high-capacity performance in two- or three-stage aggregate crushing processes. The HP350e offers up to 10% more capacity than its predecessor and includes no-backing liners for faster and safer maintenance, and more sustainable operations without hazardous backing materials.

The Metso Lokotrack® LT350HP™ mobile cone crusher is engineered for high capacity crushing, now featuring a hydraulic diesel-direct drive for streamlined performance.

Maintenance is simplified with hydraulically driven conveyors and an upgraded lubrication unit. Operator safety is a key focus, with improvements to service platforms, hydraulic hose routing, and lighting. The crushing setting can be adjusted safely from the excavator cabin using the Metso Remote IC app, enabling maximum productivity with minimal interruptions.

Sustainability is also advanced through the use of HP350e no-backing wear parts and new oil bypass filters, which extend component life and reduce environmental impact.

The LT350HP is available with two feeder configurations: a belt feeder and a grizzly feeder (also known as a TK feeder). The grizzly feeder removes excess fines before the material enters the crusher cavity, which can increase overall capacity by up to 20%. In addition to boosting throughput, the grizzly feeder helps stabilize the Lokotrack train setup and maximizes the performance of the primary crusher.

The LT350HP is available with two feeder choices: belt feeder and grizzly feeder, also known as TK feeder. With the grizzly feeder excess fines are removed before going to the crusher cavity. This gives up to 20% additional capacity. Grizzly feeder stabilizes the Lokotrack train combination and maximizes primary crusher capacity as well.

Metso Lokotrack crushers and screens come with Metso IC™ process control system that optimizes the entire crushing and screening process to keep the process going in optimum capacity and protecting the machinery. IC process control enables one-button start and stop, built-in troubleshooting, and a wide range of parameter settings. It controls all the machines in the crushing and screening process keeping the production on optimum level. The crushing setting can be adjusted safely from the excavator cabin using the Metso Remote IC app ensuring maximum production without unnecessary stops.

The LT350HP can be combined with primary crushers such as the Lokotrack® LT120, LT400J, or LT7150 Barmac® crusher, and with mobile screens like the Lokotrack® ST2.8, ST3.8, ST4.8, or ST4.10 for an efficient and flexible crushing and screening process.

To keep your Lokotrack® LT350HP™ operating at peak performance, Metso provides a comprehensive range of OEM parts, service kits, and global support services for mobile crushing operations.

Metso OEM parts are designed and manufactured to meet the exact specifications of your equipment. Using genuine parts ensures optimal compatibility, reliability, and safety—helping reduce downtime and extend the life of your crusher.

Metso offers pre-packaged service kits for key maintenance intervals. These kits include all necessary components for routine service tasks, making maintenance more predictable, efficient, and cost-effective. Service kits help ensure that critical parts are replaced on time, reducing the risk of unexpected failures.

Metso’s Life Cycle Services (LCS) provide structured support throughout the equipment’s operational life. These services are designed to improve uptime, reduce operating costs, and extend equipment longevity.

One key offering is the Equipment Protection Services (EPS), which includes:

- Extended warranty coverage

- Condition monitoring

- Scheduled inspections

- Proactive maintenance planning

EPS helps you manage risk and budget more effectively by minimizing unplanned downtime and ensuring your equipment stays in optimal condition.

Technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|

*) The technical details provided are based on the basic configuration and should not be used for obtaining transport permits.