Valves that perform better and last longer to help you reach your production targets

Durable lime-resistant sleeve and smooth flow design reduce wear

Quick sleeve change and self-cleaning action speed up servicing

Seals tight even with solids for safer, consistent operation

Less wear and scaling mean fewer shutdowns and smoother productio

Whether it’s water treatment, mineral processing, or flue gas desulphurisation, the Metso milk of lime dosing valve keeps your process flowing efficiently while reducing costly downtime.

- Lower maintenance costs

- Reduced downtime

- Consistent pH control

- Reliable, long-term operation

Milk of lime (Ca(OH)₂ slurry) is a difficult medium for most valves and pipelines.

Operators face issues such as:

- Severe scaling that causes valve seizure and leakage

- High abrasion from undissolved lime particles

- Frequent maintenance and unscheduled shutdowns

Plants need a valve that can handle these conditions efficiently, safely, and with minimal upkeep.

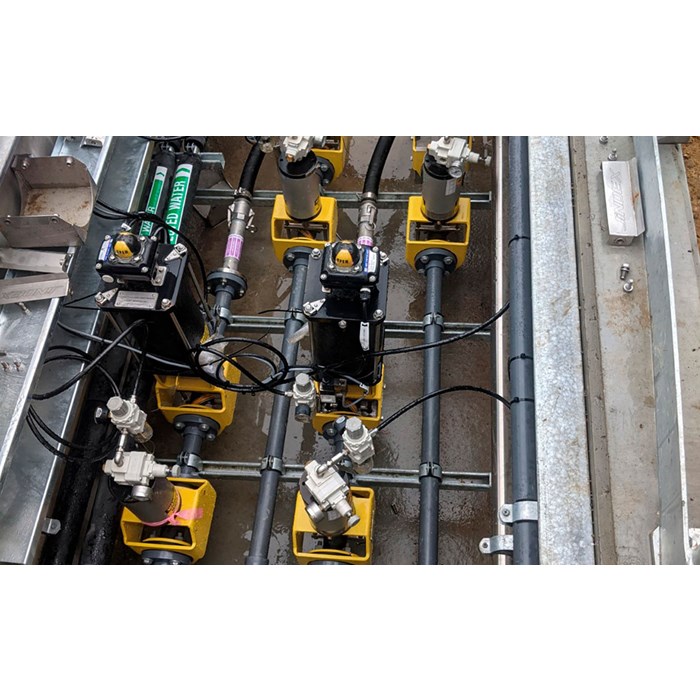

Engineered specifically for lime service, the Metso milk of lime dosing valve combines robust construction, innovative design, and proven materials to deliver long-lasting reliability.

Key features

- Smooth full-port design for reduced wear and scale build-up

- Self-sealing capability even with solids on the seat

- Double pinch closure to minimise sleeve stretch and extend life

- Patented “Fast Sleeve Change” system for quick, easy maintenance

- Flexible sleeve action cracks off scale for self-cleaning performance

- High-speed actuator reduces wear during partial openings

- Specialised “LM” Lime Rubber Blend sleeve, tested and optimised on site

- Drinking water treatment – pH control, coagulation, and colour correction

- Mineral processing – Gold leaching, flotation enhancement, and precipitation

- Desalination plants – Final pH modification

- Coal power stations – Flue gas desulphurisation

- Wastewater treatment – Heavy metal precipitation and coagulation aid