Safer and faster wear readings.

Thorough and detailed insights and accurate maintenance planning

Long-lasting liners optimized for your current conditions reduce CO2 emissions.

Reduced cost of operation with quick and easy maintenance

- Improves safety

- Minimizes inspection shutdown times

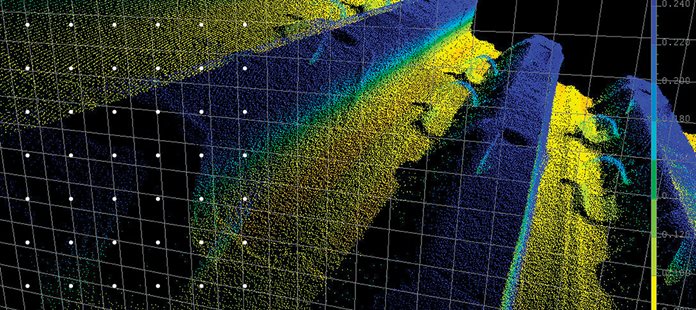

- Captures wear data on the entire mill

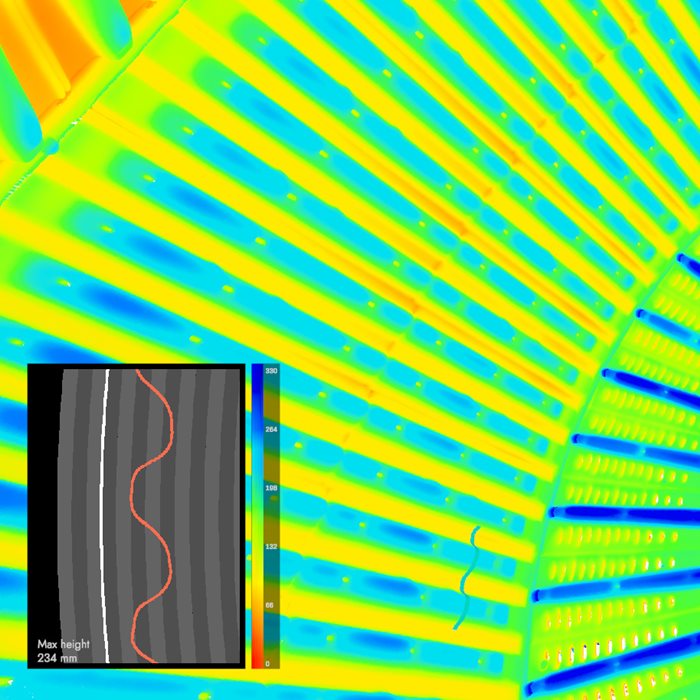

- Offers reliable reline forecasting

- Optimizes liner designs

- Improves identification of liner abnormalities to significantly reduce unforeseen liner failures

- Long-lasting liners optimized for your current conditions reduce CO2 emissions.

Metso MillMapper™ is the patented industry standard in mill liner condition monitoring. MillMapper™ liner wear monitoring allows your maintenance and operational personnel to improve the performance of your mill.

- Understanding how your linings wear has a direct impact on the performance of your grinding mill.

- Metso’s wear management solutions harmonizes liner life cycles, optimize throughput and uptime and empower better decision making with accurate wear reports and thorough analysis and wear forecasts.

- Knowing the current and historical wear rates, wear behavior, and performance of the mill is a prerequisite for liner optimization.

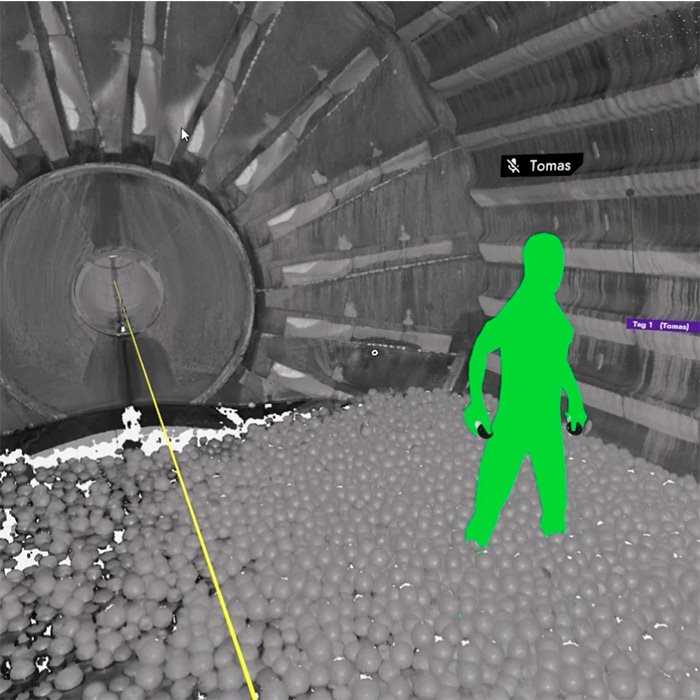

Enter your mill virtually with MillMapper™ 3D view and get a 360 view of all your previous scans.

Invite collaborators in MillMapper 3D view, as colleagues or Metso experts, to look at the mill together. Help you to free up resources as you can do a virtual inspection at any time and doesn't requires travel to site.

Talk to our sales team to learn more!