Benefits

Improves recovery rates and flotation cell throughput efficiency

Designed to fit with Metso flotation cells for fast setup and smooth operation

Enables better separation results and operation stability

Built for long-term durability, low maintenance and less energy use

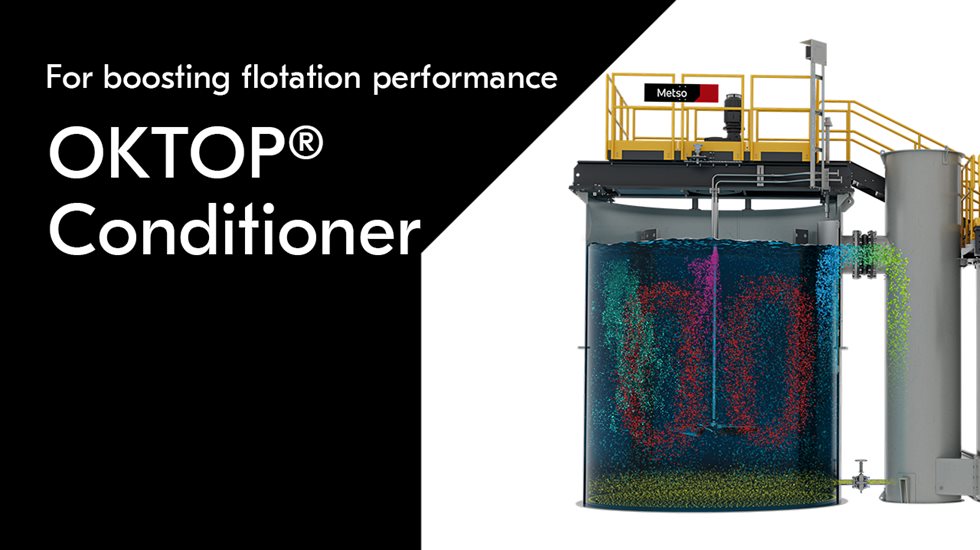

Metso offers two standard OKTOP® Conditioner options: medium duty and high duty, chosen according to particle size, solids density and slurry gravity.

For special applications, Metso also provides custom configurations such as high-intensity and heated or cooled conditioners.

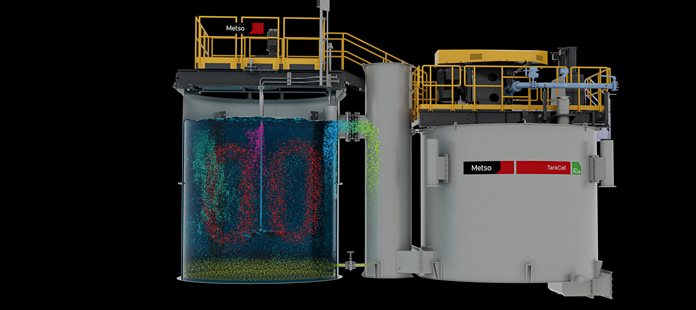

How the Metso OKTOP® Conditioner works

In case of off-spec particles coming to the conditioner caused by upstream process disturbance, Metso offers an optional SandGate™. This feature helps transfer these larger particles from the conditioner to the flotation cell without disrupting the process, adding flexibility and control to the operation.

In addition, the conditioner can be equipped with the OKTOP® SandSense™ probe, which detects sanding on the tank floor and alerts operators to potential solids buildup, helping to maintain continuous and stable operation.

Optional auxiliaries include:

- SandGate™ valve

- SandSense™ instrument

- Stairs for the connection to next equipment

- pH probe / Redox sensor

- Slurry inlet nozzle from first conditioner and more

- Density measurement for slurry with pressure instruments

The OKTOP® Conditioner can be seamlessly integrated with any Metso flotation cell, supporting fast delivery, installation and start-up.

Metso OKTOP® Conditioner: available duties*

{{decodeHtmlEntities(field.label)}} |

|---|

*For case-specific applications, Metso also provides high-intensity and heated or cooled conditioners.