Process performance, stability

and flexibility

Reduced fuel consumption and operation cost

Reduced CO2 footprint

Operation insights and integrated best practices

Get more out of your sinter plant operations without making any hardware modifications

Key benefits

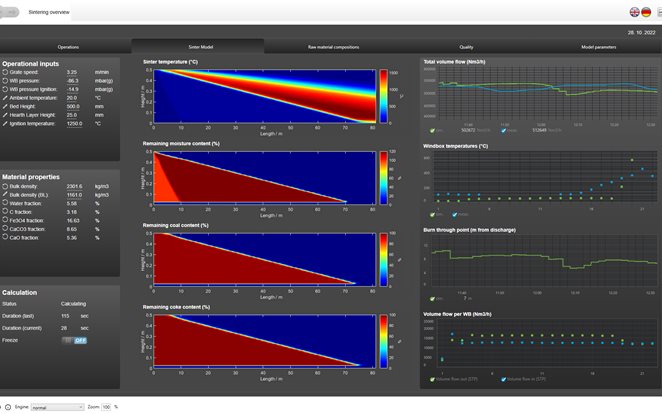

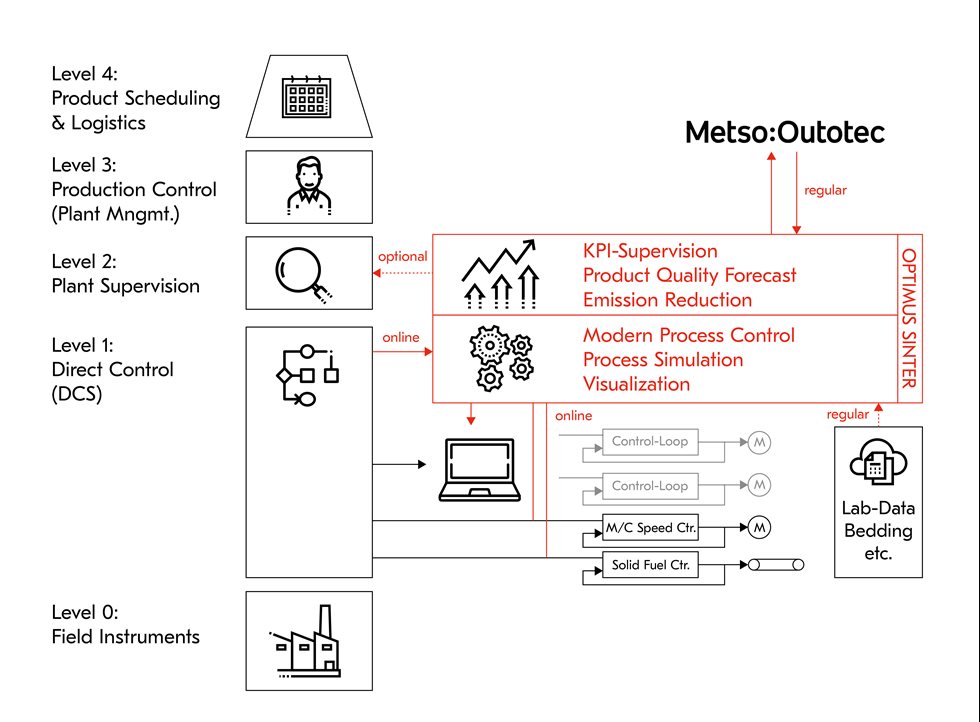

Optimus Sinter has a thermodynamic model at its core. This was developed using Metso’s unparalleled process expertise, years of experience in designing, delivering and commissioning of hundreds of sinter plants all over the world, as well as a strong know-how of process modelling in a variety of different metallurgical processes.

Based on actual raw material data, the process data from DCS and the proprietary process model Optimus Sinter can holistically facilitate:

- Up to 2% increase in gross sinter production

- Up to 4% improvement in electrical energy consumption

- Reliably reduce the solid fuel consumption

- Deep online insights into sinter process assisting operational adjustments and onboarding of operators

- Optimal dosing of solid fuel reduces emissions

- Adjustment of fan operation to process requirements enables electrical energy savings

- Maximize production capacity while maintaining product quality at required levels

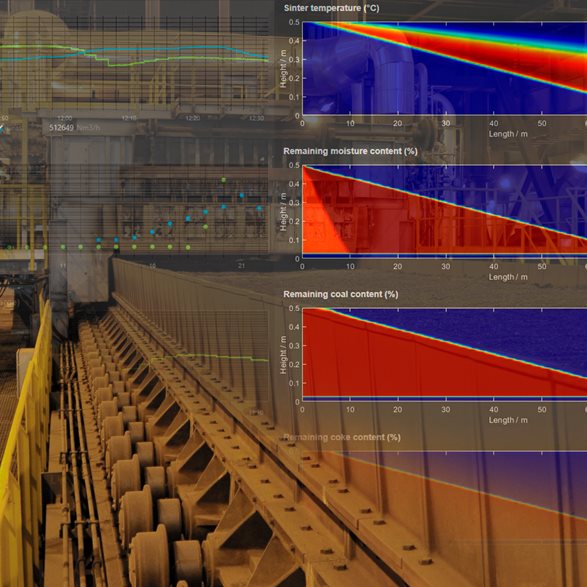

Continuous real-time data analysis

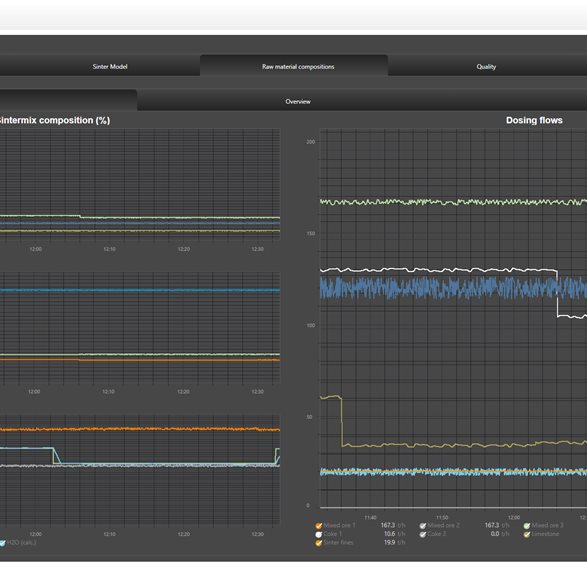

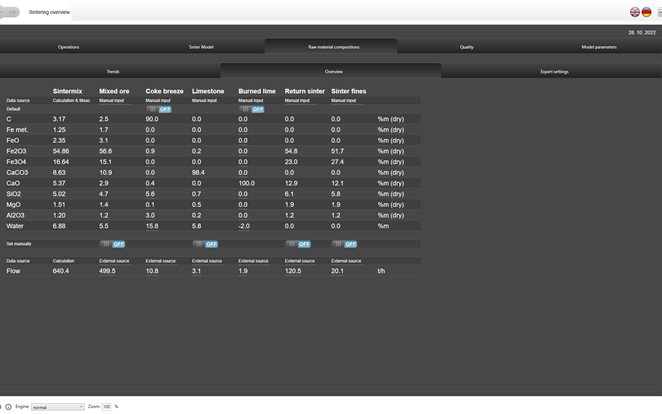

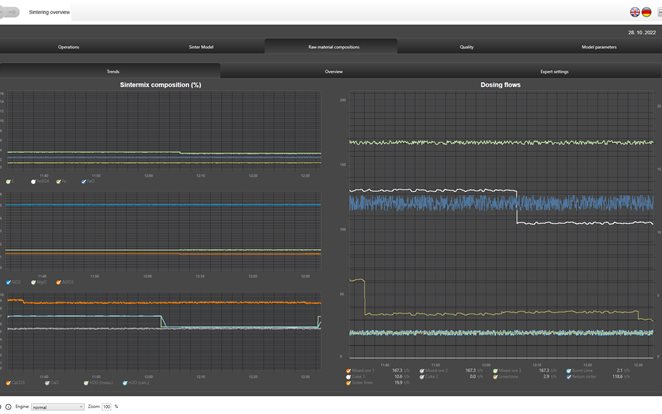

Data insights offered by Optimus Sinter

- Online, real-time process calculations

- Monitoring of relevant process parameters and KPIs like energy consumption and CO2 footprint

- Visualization of chemical and physical processes and temperatures in the sinter bed

- Online optimization of the feed material mix

- Real-time forecast of product quality (sinter strength, Fe/Fe2+ content, basicity)

- Improved Burn-Through-Point (BTP) calculation