Low total cost

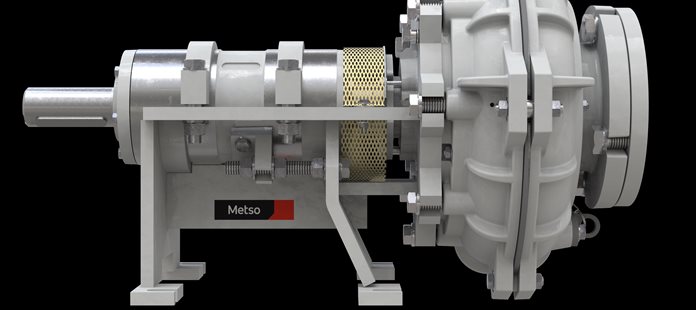

The result of over 60 years of experience from thousands of pumping applications.

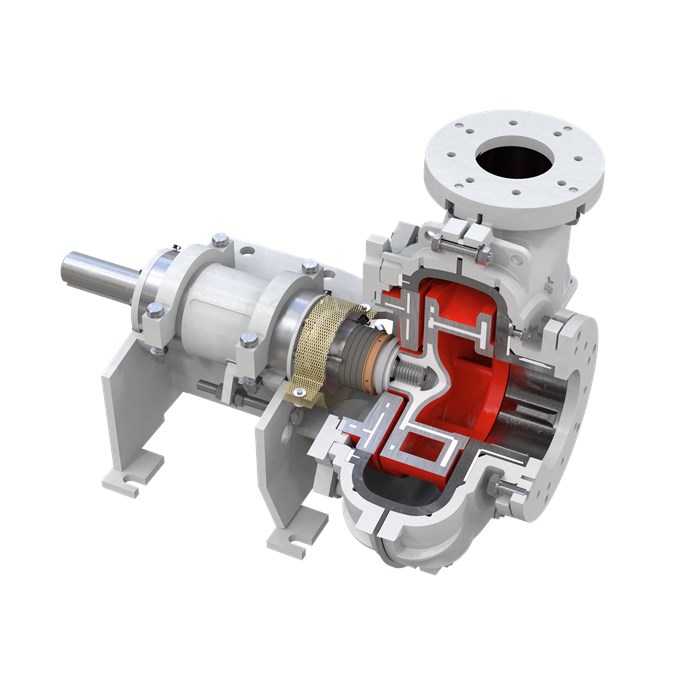

Low power consumption

Optimal power utilization. Operate close to the best efficiency point. Improved hydraulic efficiency.

Long wear life

Wear parts of highest quality hard metal, rubber and corrosion-resistant materials. Extra thick sections at known points of wear.

Reliability in operation

Pumps and parts are manufactured under total quality management in ISO certified production units.

Product offering

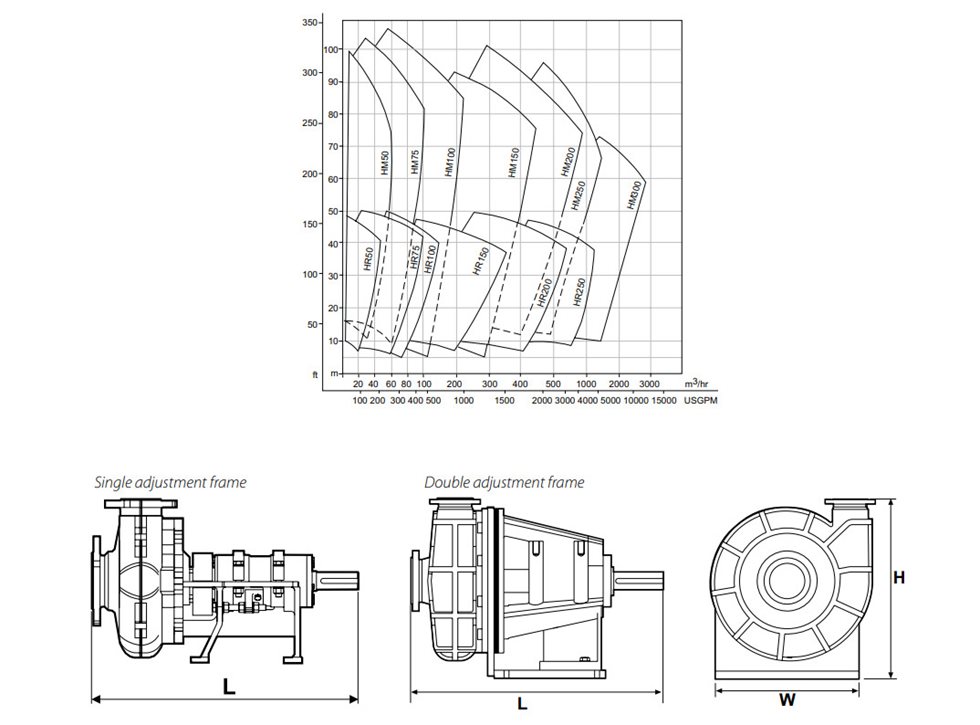

H-range

Made for the most arduous industrial slurry pumping applications. Consists of hard metal lined (HM) and rubber lined (HR) pumps.

- Flow rates to 2 800 m³/h – 10 000 USGPM

- Heads up to 100 m – 330 ft

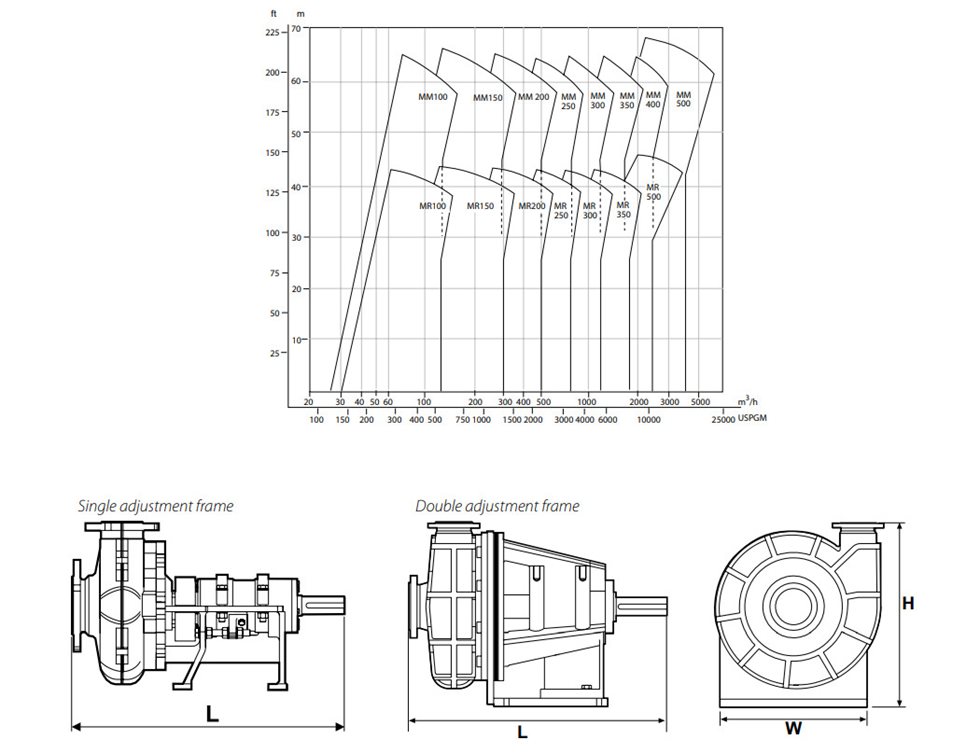

M-range

Designed for abrasive duties and medium heads in general plant transfer applications. Covers hard metal lined (MM) and rubber lined (MR) pumps.

- Flow rates to 5 000 m³/h – 20 000 USGPM

- Heads up to 60 m – 200 ft

To make Orion Series slurry pumps easily fit to your application in any processing plant, the pumps are available with various motor arrangements such as:

- Direct coupled

- Overhead mounted

- Side mounted

- Reverse overhead mounted

MRE Series horizontal slurry pumps offer a wide range of world-class and robust rubber lined solutions for abrasive pumping applications. Available in nominal sizes 100, 150, 200 and 250.

- Mining and mineral processing

- Hydrocyclone feed

- Mine refuse and tailings

- In plant slurry transfer pumps

- Industrial processing

- Coal and power plant ash

- Sand and gravel

- High efficiency hydraulic design ensures optimal power utilization

- Range optimization ensures operation close to the best efficiency point

- Wear parts of highest quality hard metal, rubber and corrosion-resistant materials

- Interchangeability of hard metal and elastomer parts to provide the best solution for each individual application

- Specially developed features provide trouble-free operation and a minimum downtime improving the cost effectiveness.

- Reliable gland seal options to meet individual requirements, using expellers, flushed glands or mechanical seals

- Pumps and parts are manufactured under total quality management in ISO certified production units

IMPELLER OPTIONS

- Standard closed impeller

- Induced flow (Vortex) impeller

- Fully recessed induced flow (Vortex) impeller

SHAFT SEALING OPTIONS

Full flow

Use for suction conditions not suitable for centrifugal sealing when product dilution is not important. Full flow provides the longest packing wearing life.

Low flow

Use for suction conditions not suitable for centrifugal sealing when product dilution needs to be minimized.

Standard expeller shaft seal

Used for no product dilution against positive suction head without leakage.

Metso slurry mechanical seal

Used for zero stuffing box leakage or product dilution. Available as single slurry type mechanical seal or double mechanical seal with external barrier fluid required.

Orion Series slurry pumps can also be supplied in a variety of special configurations:

- HP – High Pressure: Same as HM with heavier duty case for higher pressure.

- HG – Heavy-duty Gravel: Suction and discharge flanges are the same size and impeller has less vanes to pass larger material size.

- HT – Heavy-duty Tunneling: Same as HM with special 90° elbow cast into the casing.

- HH – High Head: Larger diameter impeller for a given flange sizes.

Contact your local Metso slurry pumping experts for additional information.

Parts and services for slurry pumps

Orion Series H-range technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|

Orion Series M-range technical specifications

{{decodeHtmlEntities(field.label)}} |

|---|