Proprietary technology including OKTOP® pCAM reactor, thickeners, filters, analyzers to form core of the process

Lower energy and water consumption with Metso technology

In-house process development, pilot and bench scale plants for testing

Key drivers for battery precursor industry

Growing emphasis on high performance batteries driving the demand for high quality precursor materials

Precursor is critical to both the performance and cost-competitiveness of a lithium-ion cell

Growing demand for sustainable precursor materials to address environmental impact and social responsibility in supply chain

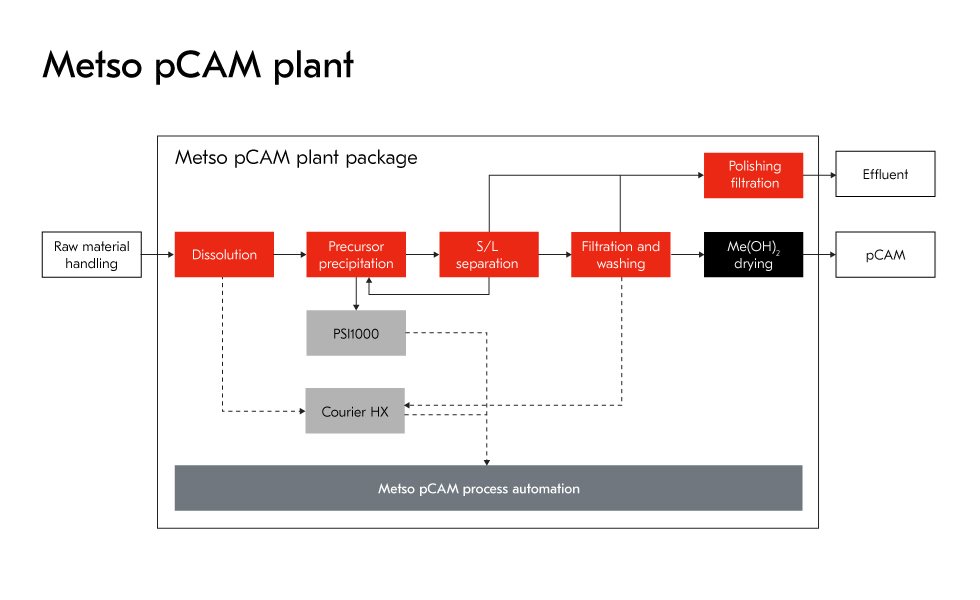

Metso pCAM plant

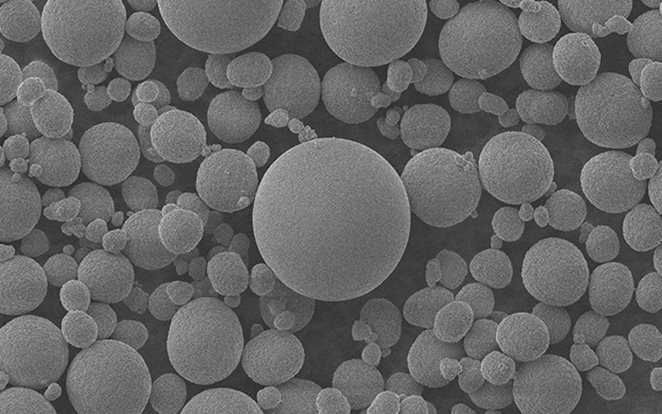

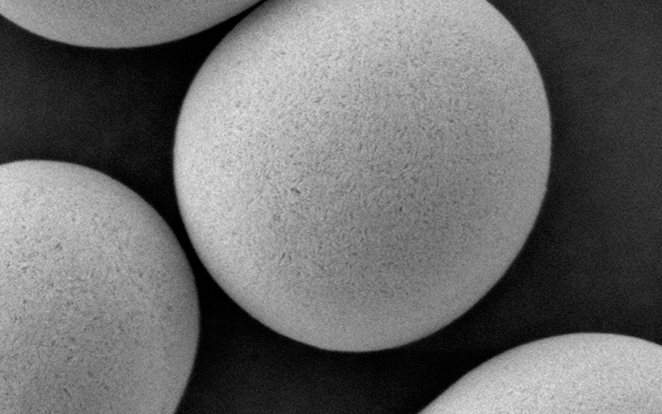

Centred around OKTOP® pCAM reactor, PSI® 1000 particle size analyzer, and pCAM process control, Metso’s pCAM plant integrates advanced technology and decades of know-how to ensure an energy-efficient and sustainable process. Backed by world-class research & and testing capabilities, Metso’s pCAM plant is an integrated solution for all co-precipitated chemistries.

Core attributes

- Proprietary technology including OKTOP® pCAM reactor, thickeners, filters, analyzers to form core of the process

- 1st western pCAM plant provider

- In-house process development, pilot and bench scale plants for testing

- Batch, semi-batch, and continuous operation with one reactor setup

- Low energy and water consumption with Metso technology

- On-line analyzers to ensure high production rate

Industry’s most comprehensive scope of supply

Sustainable pCAM process

Simulation based LCIA (Life Cycle Impact Assessment) by Metso

Key findings:

- Water consumption potential ≈ 52% reduction

- Climate change, CO2 ≈ 31% reduction

- Electric usage ≈ 27% reduction

OKTOP® pCAM reactor:

-

- High throughput

- Smaller footprint

- # of reactor to meet 40 000 tpa production, 37% reduction

- Improved yield due to high automation/digitalization level and on-line analyzers