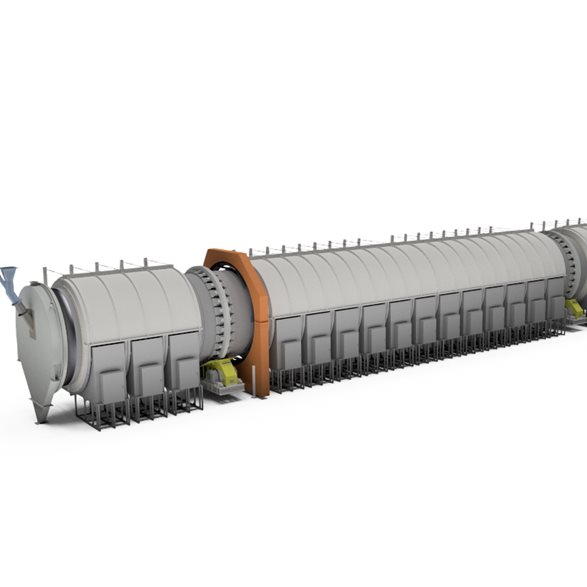

RotarEkiln: A greener, efficient indirect rotary kiln

- An alternative to current indirect kiln design

- No direct use of fossil-fuels for heat source

- No CO₂ emissions created in furnace

- More flexibility and control of temperature along shell length possible

- >20% higher efficiency than traditional fuel-fired indirect kiln

- Kiln shell diameters up to 5 meters

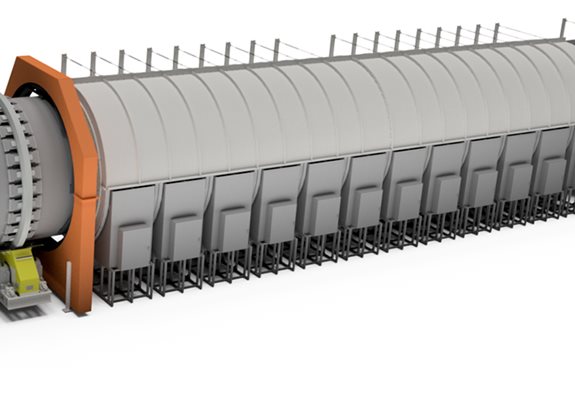

Features

The RotarEkiln’s modular heating sections can be designed identically to allow interchangeability and common spare parts. Length increments are catered to each application to offer superior temperature control over fuel-fired designs.

Metso RotarEkiln offers:

- Interchangable heating modules

- Spare modules for maintenance procedures

- Modularity facilitates precise temperature control

- Possible emitter bank expansion in field to accommodates changes in process demand

- Purge air fans for dust mitigation:

- Maintains clean furnace environment

- Is useful for cooling during shutdown

- Fiber blanket seals and shroud insulation promoting high heat retention

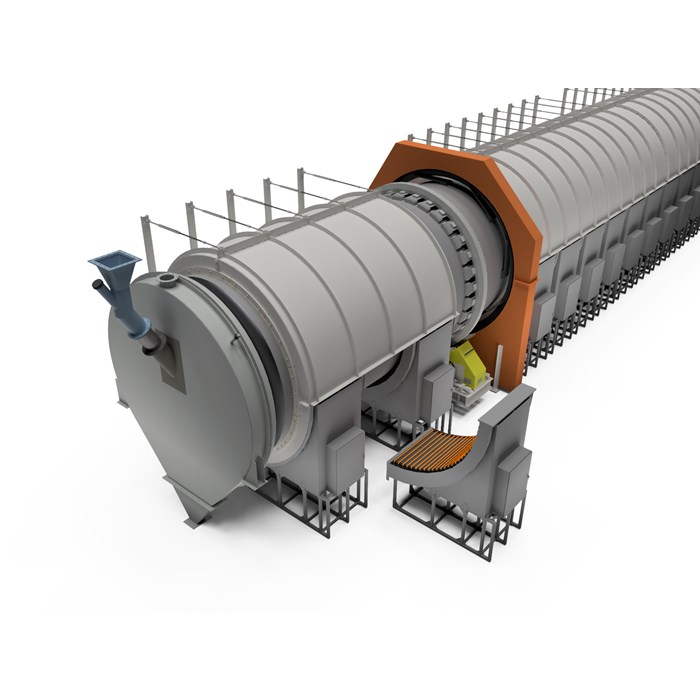

Key components

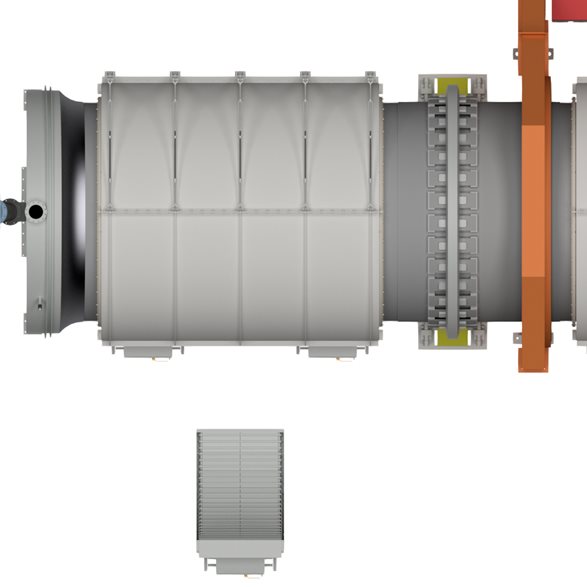

Hoods at feed and discharge ends of the kiln shell to efficiently control transfer of gases and solids. Special seals between hoods and rotating shell minimize ingress air and maintain required process atmosphere.

Kiln shell is heated externally, therefore selected material must withstand temperature, corrosion, and/or abrasion.

Enshrouding furnace: heating up kiln shell with electric emitters while isolating process gases from environment.

Electric emitters: Resistive heating elements in varying lengths based on voltage supply. The element face temperatures can exceed 1500°C transfer infrared radiation to the kiln shell.

Heating modules with electric emitters, insulation, wiring, and junction boxed for fixed kiln length increments. Easily serviceable, replaceable, and exchangeable.

Heating zones: Modules in series are actuated to maintain a temperature setpoint.

Furnace seals for highest efficiency and protection of elements and personnel.