Up to 20% lower cost &

height than concrete

70% faster feasibility

25% faster delivery &

15% faster erection

Metso components

+150 configurations

~20 days relocation

+30% capacity with the SuperiorTM MKIII crusher, +40% lower downtime with SmartStation

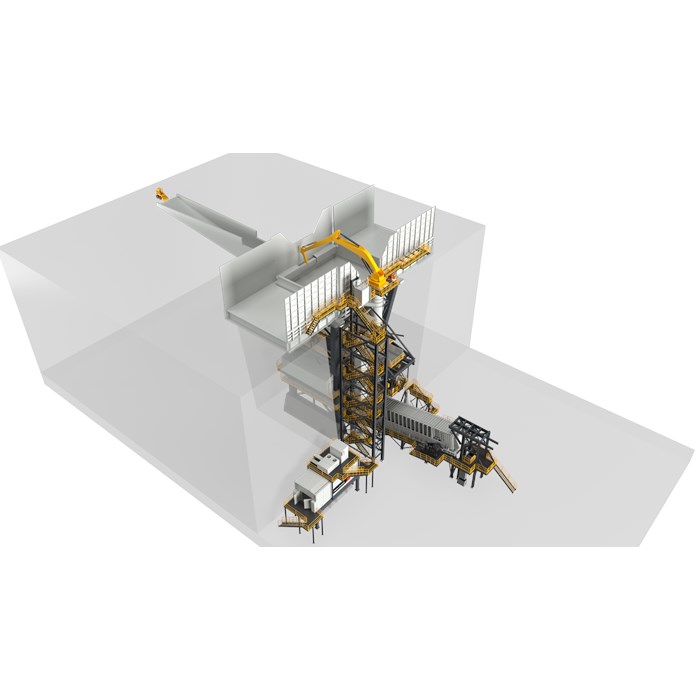

The Foresight™ SMPG station design in terms of capacity are driven by a few factors:

- Truck sizes

- Average hourly production requirement in tons

- The run-of-mine (ROM) feed particle size distribution

- Required maximum product size as P80 or P95

With this knowledge, the feed hopper, vault, truck ramps, crusher and discharge feeder can be selected accordingly.

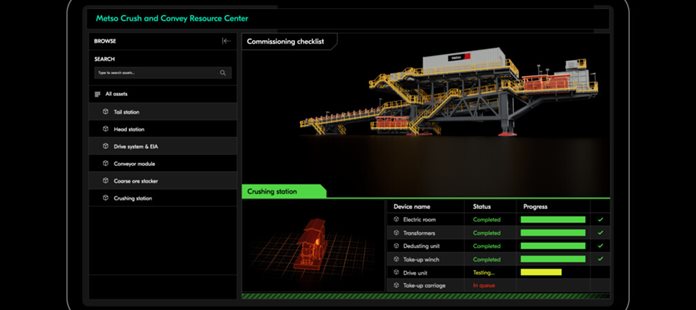

The Foresight™ SMPG station electrification & automation contains:

- E-house including switchgear, MCCs and VFDs

- Cabling & instrumentation

- Control & automation

The Foresight™ SMPG station’s modular and compact configuration allow for Apron feeder or Belt feeder discharge. Apron feeders offer the highest availability and lowest operating cost, demand a higher station height and CAPEX than a Belt feeder discharged plant though.

Metso SmartStation for process control boosts productivity. It allows for

- advanced control for process balance

- automatic wear compensation tracking product top–size

- automatic speed adjustment for large block acceptance

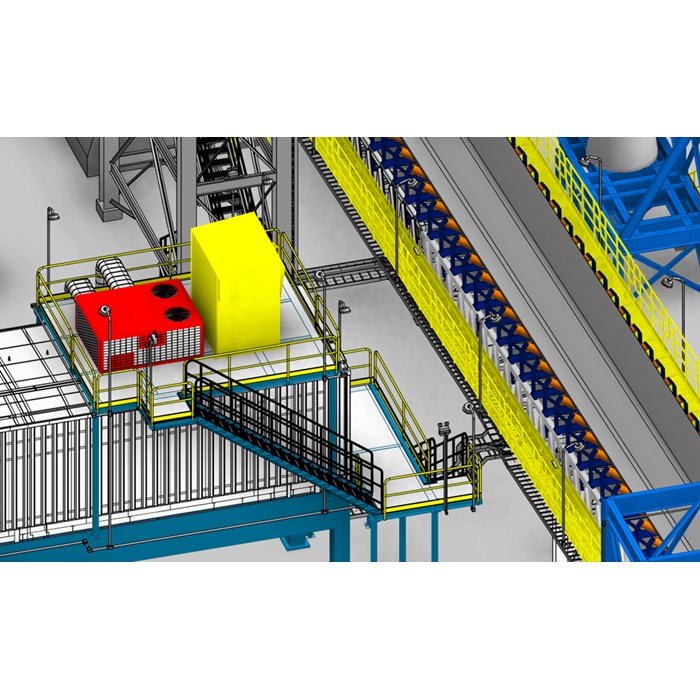

The dust control configuration area allows matching regulatory, operational and material requirements with the correct suppression and/or collection equipment.

The parts that make up a dust control configuration for the SMPG station are:

- Wet dust suppression

- Dry de-dusting

- Cover hoods

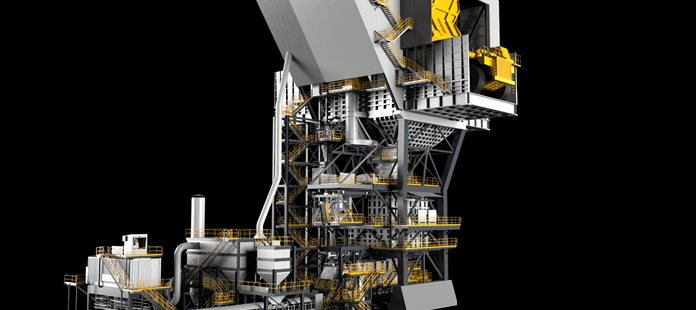

Metso’s Foresight™ SMPG has the highest inbuilt safety and maintainability of semi-mobile primary gyratory plants on the market.

Our service teams support, operate and maintain crushing plants and conveying equipment around the globe and their feedback is continuously reflected in our design improvements. This enables Metso to match plant design and on-site performance, in operation and maintenance, to deliver the tons on a continuous basis, at highest availability.

Find below what makes us up such a safe and maintainable solution:

- Eccentric cart and pin gate

- Jib or bridge crain

- Hoists & mainshaft stand