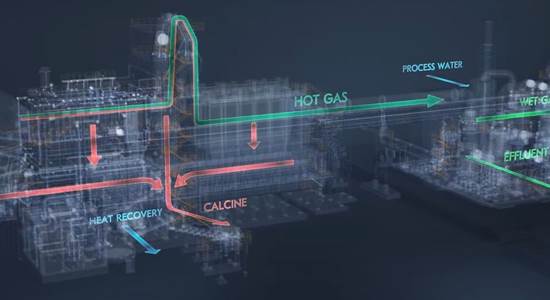

Increase safety and productivity through better awareness of process conditions.

- Increases safety

- Collects cooling water data with few instruments

- Lowers investment costs and the need for maintenance through a patented solution

- Enables optimization of water consumption

- Increases furnace lifetime through monitoring

- Includes easy-to-use software with intuitive multi-user interface

- Allows easy upgrading of the header