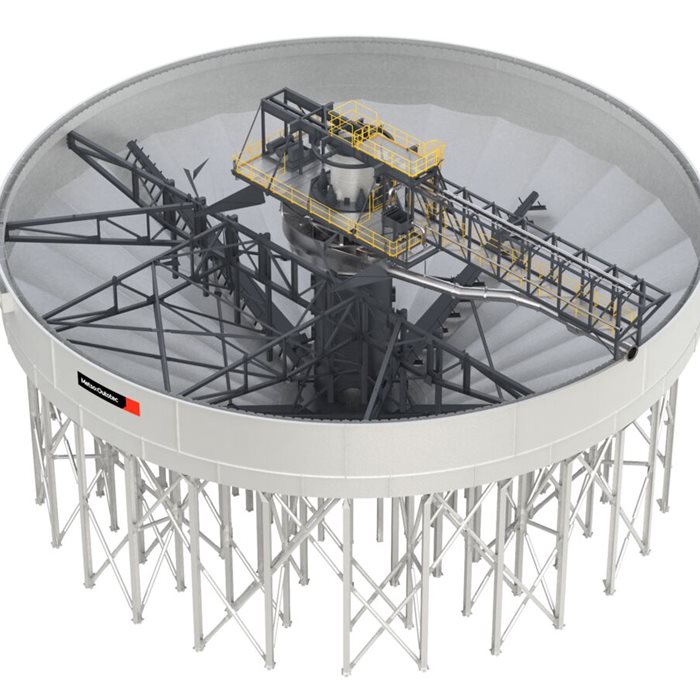

Upgrades that improve performance to help you reach your sustainability targets

Reduced reagent consumption

Less need to clean process water in dams or tanks and fewer solids in the returned process water

Less need to clean process water dams or tanks

Reduced or eliminated froth to overflow

- Improves minerals recovery

- Decreases operating costs through reduced reagent consumption

- Results in cost savings as less need to clean process water dams or tanks

- Reduces the amount of solids in the returned process water

A range of options are available depending on the level and tenacity of the froth:

- Rotating floating boom

- Sprays and baffle

- Effective for light and fluffy froth

- Boom and beach

- Sprays and baffle

- Floating boom replaced with rigid boom

- Beach collection point with tank wall penetration for froth removal

- Highly effective on denser more tenacious froth

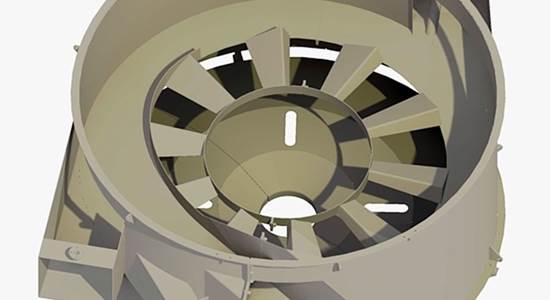

- DA tank

- Stops froth from entering thickener

- Feed enters tangentially to create a vortex to aid deaeration

- Thickener feed is withdrawn from below the liquid level to prevent air and froth entrainment

- Process review

- Engineering study

- Upgrade, which may include:

- Rotating boom

- Sprays and piping

- Baffle

- Beach

- DA tank