Why partner with us?

Reliability

Reduce unplanned shutdowns

Cost

Reduce operating and maintenance costs

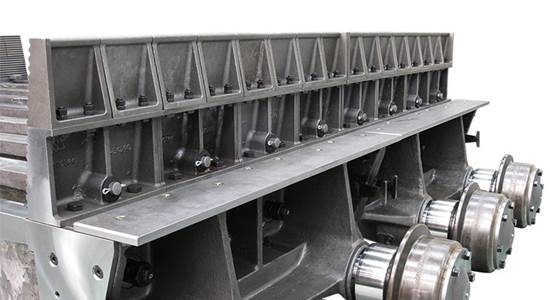

Longevity

Increase the lifetime of traveling grate components

- Reduces maintenance needs and operating expenses

- Increases the lifetime of travelling grate components like pallet cars, sealings, rails, and gear rims

- Improves sealing

- Reduces electrical energy consumption