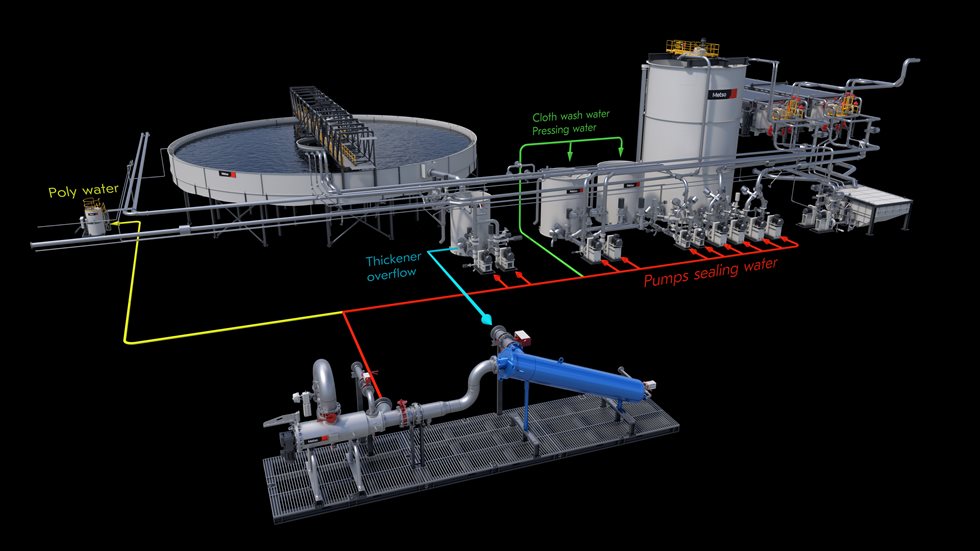

Webinar: Water Treatment Skids

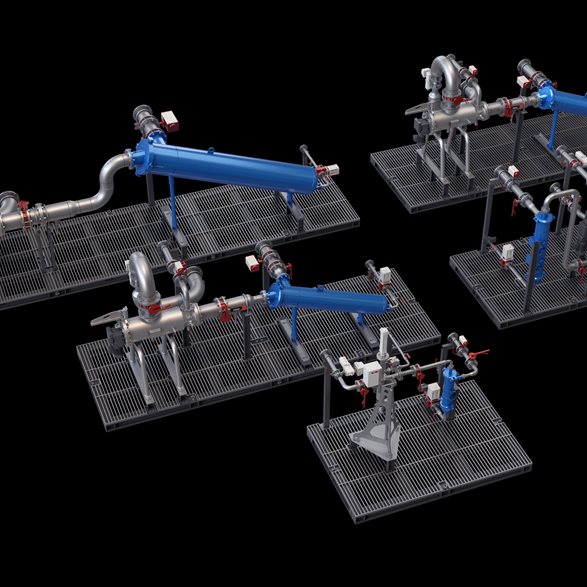

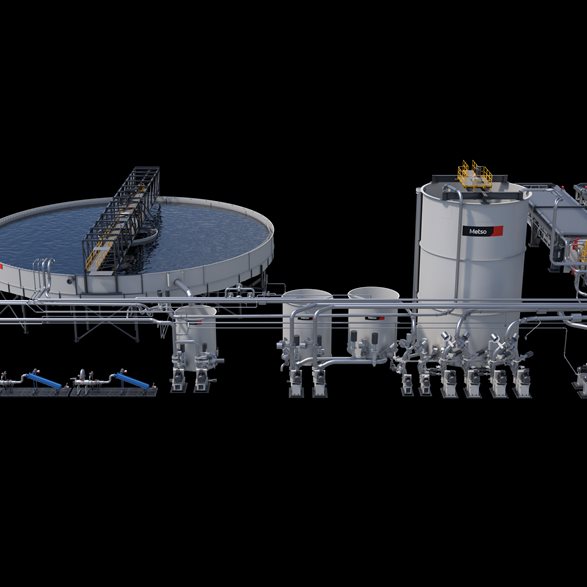

Join us for a webinar where you will get to know Metso’s Water Treatment Skids (WTS), a modular, plug-and-play solution revolutionizing industrial water treatment. Learn how WTS uses centrifugal separation and self-cleaning filtration to deliver consistent water quality, reduce downtime, and improve process reliability with minimal environmental impact.