About Trellex® Cerlag ceramic pulley lagging

Application

Trellex Cerlag ceramic pulley lagging can be applied to conveyor drive, tail, snub, bend or take-up pulleys when there’s a requirement for more grip than what rubber lagging provides or longer service life as a result of higher wear resistance than rubber.

Ceramic pulley lagging is used for pulleys operating under extreme conditions. It is suitable for wet, clay containing, muddy and abrasive materials. Also for belts under very high tension. Especially suitable for drive pulleys subject to extreme wear to eliminate slippage.

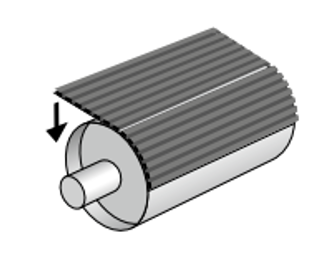

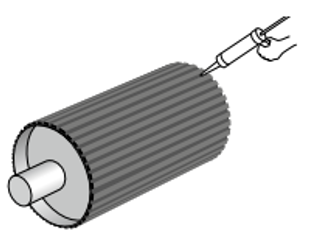

Trellex pulley lagging should be applied according to our application procedure using Trellex Steel Primer and Trellex Greenbond adhesive.

Design

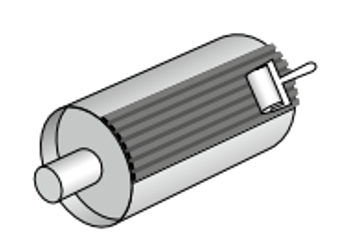

Cerlag ceramic lagging has vulcanized alumina tiles on rubber with rubber bonded to optimized area of the tile to ensure tile cushioning and better adhesion strength. Tiles provide high abrasion resistance. Rubber backing used is rubber compounds abrasion resistant and flexible to provide flexibility to the tile. Cerlag ceramic pulley lagging is made of a two different rubber layers extruded together. The top layer being the high abrasion resistant layer to which the tiles are vulcanized onto and the bottom layer being the adhesion CN bonding layer.

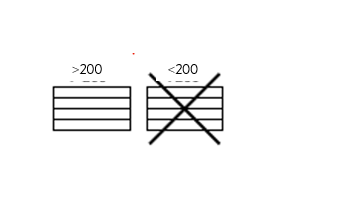

Our specially formulated neoprene-based CN bonding layer is engineered to achieve ultimate adhesion when bonded to steel pulley surfaces. Metso’s CN bonding layer has a buffed finishing to provide an increased surface contact area that increases adhesion. Cerlag ceramic lagging is 250 mm wide as standard (500 mm as MTO) to ensure easy handling and application. It can be supplied in thicknesses from 12 mm to 25 mm. Thicker rubber allows more deflection of the tiles under the belt. This property provides additional reserves with extreme belt tensions, especially in combination with fabric belts with high elongation or low cover thickness on the running side.

Ceramic lagging with dimple tiles issued on drive pulleys to increase grip and Ceramic lagging with smooth tiles is used on non-drive pulleys to increase wear resistance/service life.