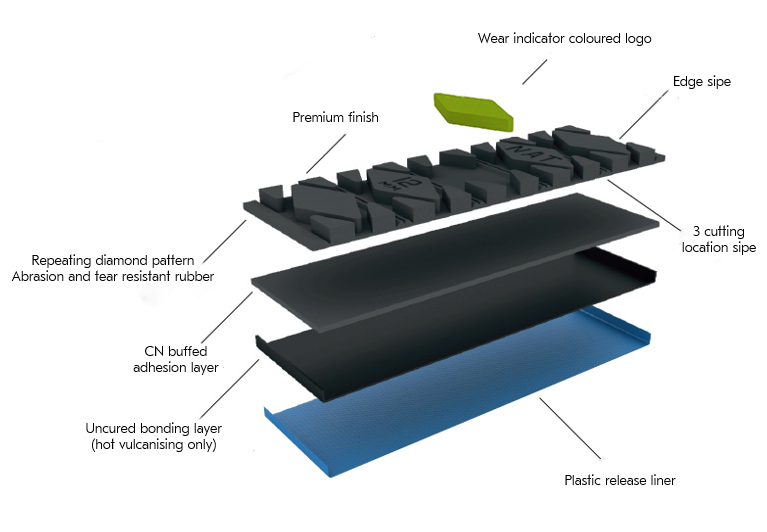

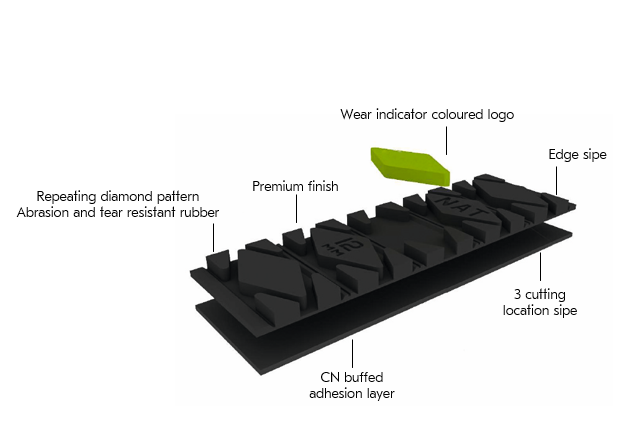

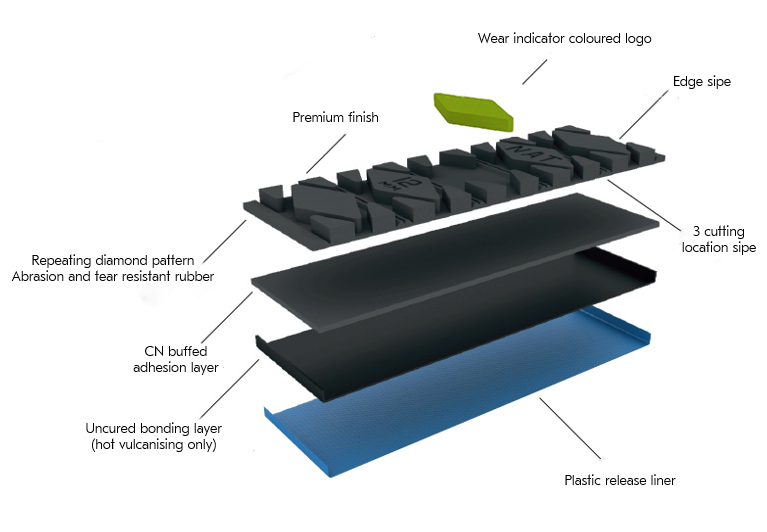

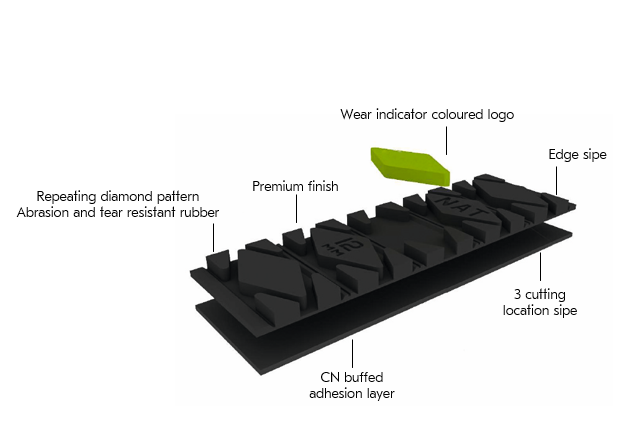

Material: Wear Rubber 65 ShoreA, Buffed Bonding Layer-CN

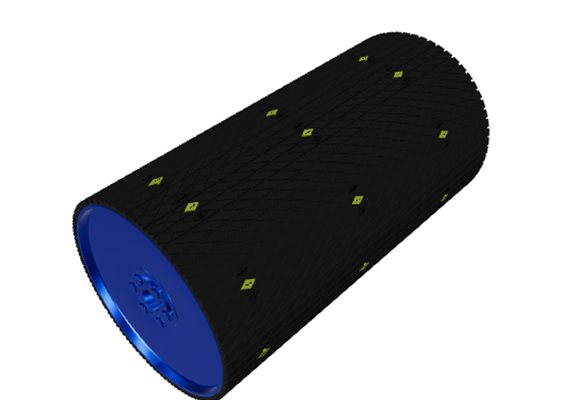

Wear side: Diamond-pattern

Standard Installation: Cold bonding (Hot vulcanising available on request)

Fire Resistant & Anti Static, FRAS: Available on request

Width: Standard 250mm (500mm available on request)

Cold bonded adhesion: Metso rubber lagging should be applied according to the application procedure using Trellex Steel Primer P5 (P/N 2322060) and Trellex Greenbond adhesive (P/N 2322040). These have been formulated to contain ingredients that chemically interlock with components in the CN/CL bonding layer. Cold bonding adhesion values exceeding 12 N/mm.

Wear indicators: Rubber lagging for medium & heavy applications are using wear indicators. Green color standard rubber & Orange color FRAS.

Hot Vulcanising: Available on request. Hot vulcanising lagging is supplied with a 1,2mm thick uncured rubber layer applied to the back and sides. Packed in plastic to protect and keep the uncured bonding layer fresh and free from contamination until it’s applied to the pulley. Application by an approved applicator will guarantee a 100% rubber tear bond between the lagging and the pulley shell with typical adhesion values exceeding 20 N/mm.

Hot Vulcanising: Available on request. Hot vulcanising lagging is supplied with a 1,2mm thick uncured rubber layer applied to the back and sides. Packed in plastic to protect and keep the uncured bonding layer fresh and free from contamination until it’s applied to the pulley. Application by an approved applicator will guarantee a 100% rubber tear bond between the lagging and the pulley shell with typical adhesion values exceeding 20 N/mm.

Hot Vulcanising: Available on request. Hot vulcanising lagging is supplied with a 1,2mm thick uncured rubber layer applied to the back and sides. Packed in plastic to protect and keep the uncured bonding layer fresh and free from contamination until it’s applied to the pulley. Application by an approved applicator will guarantee a 100% rubber tear bond between the lagging and the pulley shell with typical adhesion values exceeding 20 N/mm.

Hot Vulcanising: Available on request. Hot vulcanising lagging is supplied with a 1,2mm thick uncured rubber layer applied to the back and sides. Packed in plastic to protect and keep the uncured bonding layer fresh and free from contamination until it’s applied to the pulley. Application by an approved applicator will guarantee a 100% rubber tear bond between the lagging and the pulley shell with typical adhesion values exceeding 20 N/mm.