Ability to efficiently screen damp and sticky material, preventing buildup

Flat surface design eliminates wire-on-wire wear, lasting longer

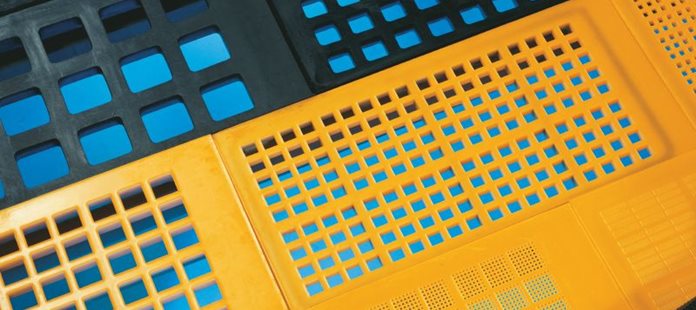

Highest open area available, with precise openings for any application

Four unique configurations to suit various screening needs

Where customer insight meets cutting-edge technology

Less blinding and pegging

With Trellex® PCL screening media, you can efficiently screen your material even in the most demanding conditions.

Whether your feed material is damp and sticky or prone to pegging, PCL will screen it and produce a cleaner product.

Each wire vibrates independently, which inhibits the buildup of material over the screening surface and thereby prevents blinding and increases the efficiency of the deck.

Longer wear life

Our manufacturing facilities with established processes and regular laboratory tests ensure constant high quality.

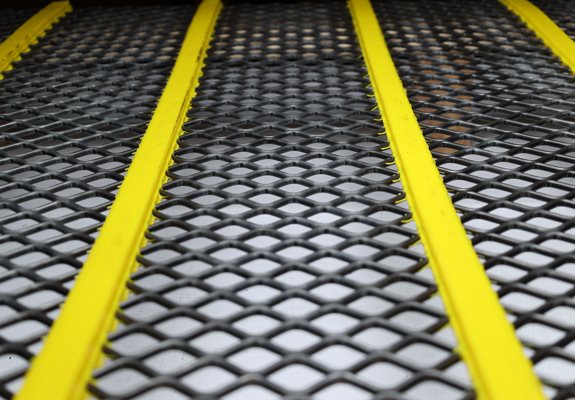

The design of Trellex® PCL offers a flat surface and eliminates wire-on-wire wear. This results in significantly longer wear life. Combining the wear resistant properties of polyurethane sealing strips with the high quality wire media, PCL lasts longer and outperforms traditional wire cloth.

Maximized open area Trellex PCL offers the highest open area available in today's market. A broad range of openings is available, all with highly accurate and precise openings - no matter your application.

Focus on safety and sustainability

Sharp edges, which are difficult to handle and pose a risk of operators being cut, are avoided thanks to the use of sealing strips. In addition, PCL can be rolled up without being damaged.

This means that it takes up less space, which in turn facilitates transport and contributes to a more sustainable society through reduced CO2 emissions.

Services and availability to keep your screen operating

The unmatched knowledge of our people and our broad portfolio of screens, media and parts make it possible for us to help you optimize your specific process according to your needs and target.

With Metso’s extensive global network, support and service is always close. In addition, improved lead-times facilitate faster maintenance and planning.

{{ title }}

• Maximum open area

• Rapid removal of fine material

• Longer wear life than traditional piano wire screens

{{ title }}

• High open area

• Removes fine material while retaining an accurately sized clean material

{{ title }}

• Exceptional cleaning ability

• Suited for applications with a high percentage of nearsize material which is prone to pegging or blinding

{{ title }}

• Capable of withstanding greater bed depths and loads

• Alternating crimped and straight wires provide very accurate sizing