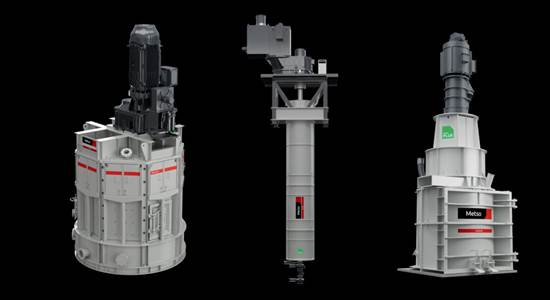

Why choose Metso stirred mill spare and wear parts?

We built your machine. We know what parts it needs.

Consistent spare and wear part performance and maximized wear life, leading to up to 45% better energy efficiency.

Safe and fast installations.

We are here to assist from choosing spare and wear parts, to installation, service, and beyond.

Longer wear life and excellent performance

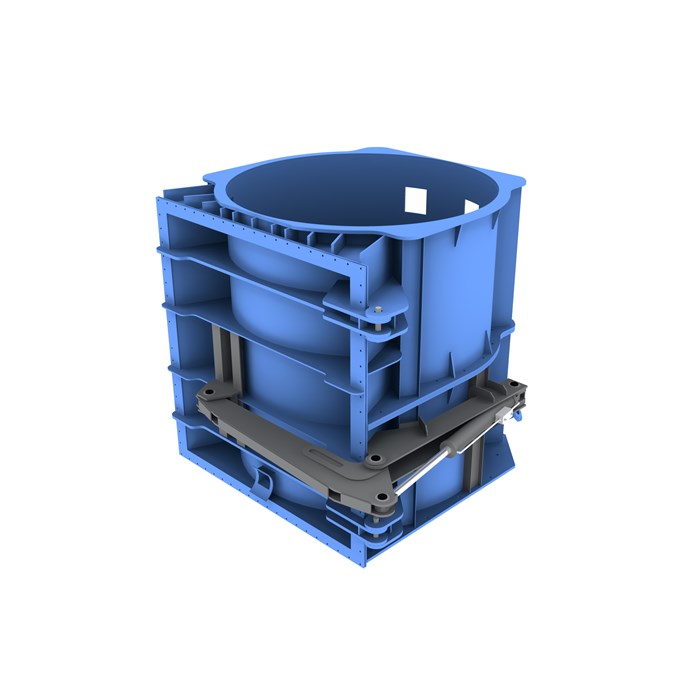

We offer a complete range of liners and spare and wear parts to protect and optimize the grinding efficiency of your Vertimill®.

- Screw liners (wear liner and end liner), that protect the permanent screw from the wear

- Wear cap, that protects the screw shaft from wear

- Orebed™ shell liners, that protect the inside wall and the door

The liners are made of carefully selected wear-resistant alloys for longer wear life and excellent performance. Safe lifting methods are available for all situations.

We offer a complete range of spare and wear parts to protect your Vertimill, optimize grinding efficiency and performance, minimize safety risks and reduce unplanned downtime.

Watch the video to learn more.

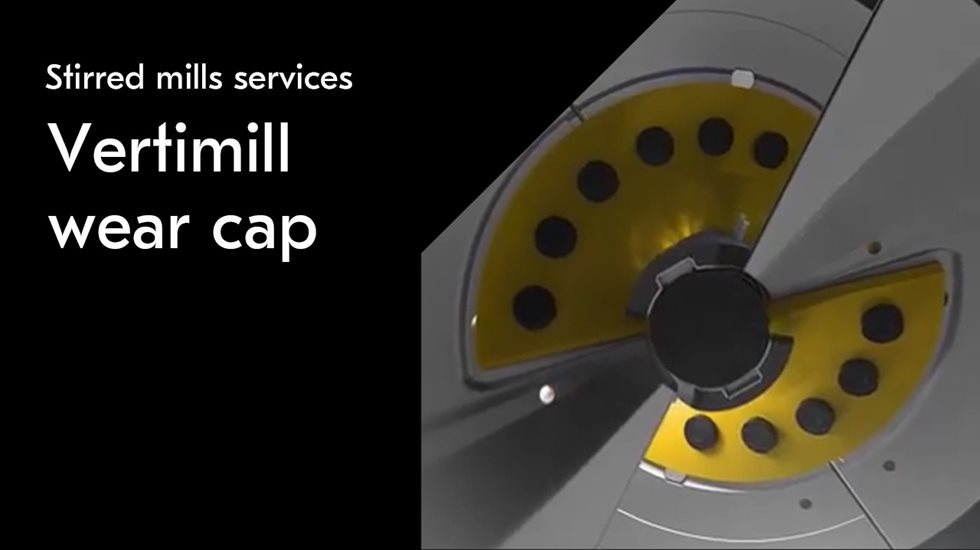

Metso offers a screw shaft wear cap replacement that is easy and safe to handle and offers improved design features to increase circularity, reduce maintenance cost and downtime.

Watch the video to learn more.

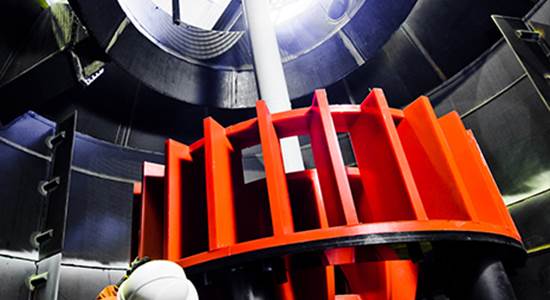

We offer a complete range of liners that protect the screw from wear and provide faster and safer installation. Wear liners are specially-designed to provide stability during installation with reusable attachment parts for greater circularity and sustainability.

Watch the video to learn more.

The drum segments and components have been designed to make maintenance simple and maintenance intervals long for more sustainable operation. The casing is flanged vertically, allowing it to be split down the center into two halves and moved apart on a railing system. After exposing the internals, changing discs and liner segments can be done individually.

Disc wear is even around the circumference. Wear is faster in the bottom part and typically the lowest discs are replaced a few times before the total set is changed. For a total set change, a spare shaft, ready for installation, is an option. Components are lined with polyurethane or rubber depending on the application.

- Grinding rotors

- Shell liners

- Stator rings

- End cap

- Bottom liner

All spare and wear parts have been designed for optimal wear life and consistent performance, which gives predictability. Implellers and side liner are made of rubber and retaining screens polyurethane.

SMD is easy, safe and cost-effective to maintain when needed thanks to simple design and the ability to change all spare and wear parts through access doors.

- Impeller arms and end plate

- Mill body liners

- Base liners

- Media retention screens

- Attachment parts

We offer specialized maintenance tools to help enhance safety and facilitate access to mill parts during relining and maintenance operations.

Download the brochure - Opens in a new window

The drive upgrade for the energy efficient Vertimill® delivers the follwing benefits:

- Advanced process control packages to increase revenue and decrease costs

- Accurate and rapid flexibility (100% more PSD testing per day)

- Fast customer return on investment (weeks)

- Potential for remote monitoring

- Reduced energy consumption