Unique know-how and leading process tools to help you reach your sustainability targets

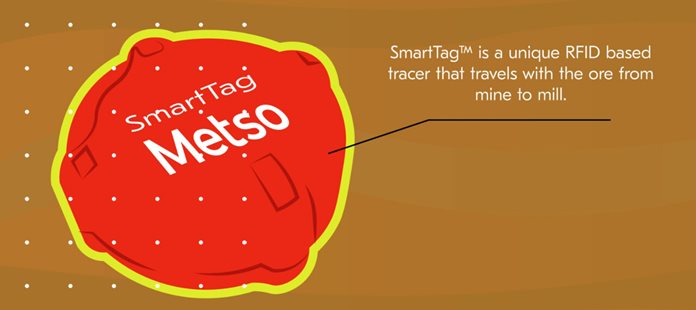

Intelligent tracking system

Unique Real-time ore tracking from mine to the processing plant and beyond

Increase performance

By implementing pro-active plant control based on incoming ore type.

Process optimization

Link the physical properties of the ore in the mine to the time-based performance data of the plant

- An inexpensive and versatile physical material tracking system. Track from the mine to the plant and then to the plant digital twin.

- Improving reconciliation by reducing the discrepancies between the expected and actual ore delivered.

- Debugging for the mine to mill process by offering insights into the root causes of performance declines, allowing operators to identify and address underlying issues promptly.

- Alert the processing plant of feed ore type and facilitate proactive changes to the plant.

Understand how different ore types impact performance