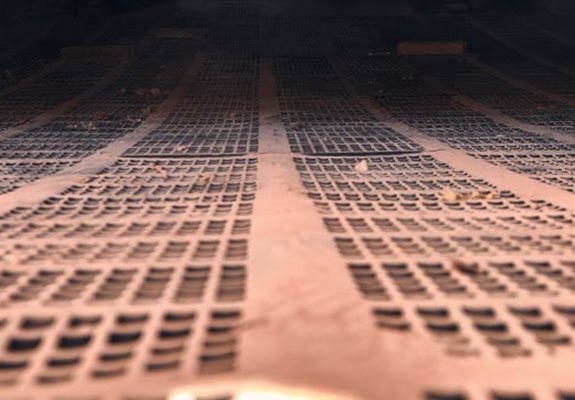

Do you want to see this on your screens or feeders?

Avoid undetected issues

Vibrating equipment inspections as Your Road to Trouble-free Operations

Higher vibrating equipment availablity

Reduced maintenance costs

Optimized end product quality

Preventive maintenance and proactive repairs

Regular inspections improve efficiency

- correct feed distribution on the screen

- feed size

- material bed depth

- feed humidity

- condition of the springs and all bolts joints

- oil or grease levels

- bearing temperatures

- drive system

- vibrator mechanisms

- condition of the screening media and reporting this into our ScreenPlanner software

* Refer to the manual you’ve received with your equipment to find the complete list

- All of above mentioned checks

- A Screencheck® inspection (see below) including

- vibrating stroke

- stroke angle

- natural frequency measurements

- steel structure measurements

- Checking current screen performance against expected performance: identify shortfalls, likely causes and potential corrective actions

- Check if installed screening media and wear linings are the most appropriate for your production process

Expert report with recommendations

ScreenCheck®

Some specific tests on screens can be done with our ScreenCheck®-tool. ScreenCheck® is a hand-held electronic testing device featuring wireless electronic sensors and automated software that precisely measures and analyzes the dynamic performance of vibratory screens. All our technicians and most of the sales representatives carry this tool with them. Are you interested in having someone from Metso test your screen, then let us know by clicking the green button at the bottom of this page.