Unique know-how and leading process tools to help you reach your sustainability targets

Decreased CO2 emissions and energy consumption with increased production per cycle

Treat and recirculate process water resulting in lower fresh or raw water intake

Through water efficiency, recirculation, recovery and extending the lifetime of the plant

OEM spare parts and automation leads to improved safety, optimized processes and preventative maintenance know-how

The rising demand for sustainably mined materials is pushing the need for more advanced technologies.

Stricter environmental regulations are shifting the focus towards tailings management and water resource efficiency.

Modern mineral processing methods are required to improve predictability and continuity of operations.

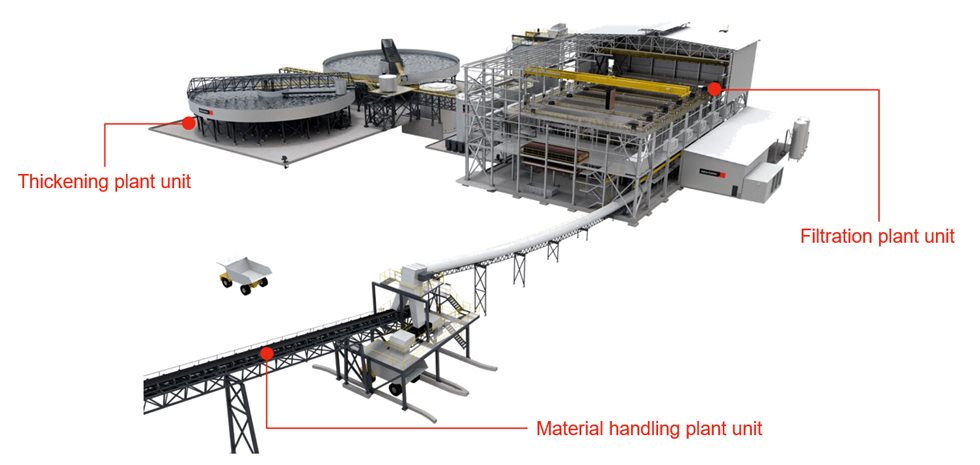

Metso offers cutting-edge technology solutions and services for any tailings management needs while reducing water use, environmental impact, risks, and costs. Using thickening, filtration and handling of tailings by conveying & dry stacking, while treating the produced water to enable reuse, we reshape the future of tailings and drive responsible management practices backed by extensive process expertise.

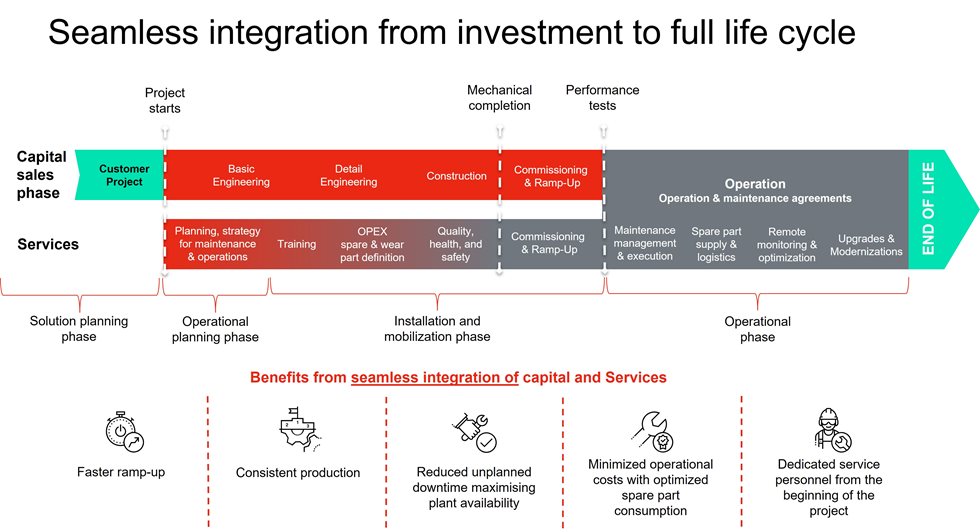

From test work to plant design and delivery, backed by life-cycle service support; our scope is configured to your project requirements, providing a sustainable and economically viable solution.

Our Reactorwell™ and Vane Feedwell provide enhanced mixing, dilution, and retention of the feed, maximizing flocculant adsorption and aggregate growth. Advanced control systems such as thickener optimizer also help in improving the overall performance of the plant unit.

Filtration plant unit Specifically designed for high-volume tailings processing leading to savings in operational and maintenance costs.

1. Solution planning phase

Verifying that all your equipment meets or exceeds the operational requirements of your solution

Our comprehensive portfolio provides global competencies and skills throughout the entire life cycle of the plant.

We provide integrated programs that include KPIs or cost-per-ton-related commitments to help our customers improve their profitability and lower their operating costs and risks.

We have strong R&D and innovation power, and we are continuously looking for new ways to introduce innovations for our customers’ benefit.

Our expertise, references, quality, experience, history, and R&D help our customers to continually improve operational efficiency year after year.

We understand our customer’s world and the daily challenges they face. Together, we can partner for positive change.

2. Operational planning phase

Looking ahead and arranging the activities and resources required to achieve the agreed goals

We offer training, spare parts, pre-operational equipment testing, shutdown planning, and asset maintenance readiness programs to equip our customers with the tools and competencies to run their plant or opt for us to run the plant with our customizable LCS packages.

Achieve a smooth production start-up and quicker ramp-up with our installation and commissioning experts who will help to ensure your equipment performs according to agreed targets.

Our professionals have extensive experience in tailings skills capabilities, materials handling, dry-based plant, paste backfill, water testing, advisory, sizing, filter feed variations as well as variations in the environment, plant and equipment to optimize minerals processing practices.

We have an extensive understanding of challenges, the timeline and costs to mitigate risks. Each customer case is different and our solutions are customizable based on customer needs.

3. Operational phase

Continuous improvement with lower costs and risks while reaching expectations

We focus on integrating performance across cost and risk while focusing on meeting customer expectations through the continuous improvement of the operational processes.

We have a global team of industry professionals who provide expert advisory, laboratory services, technology and connected services to the mining industry worldwide.

We address challenges based on customers’ plant data such as improving recoveries, de-bottlenecking processes, increasing availability, reducing energy consumption, chemical costs and water use by optimizing the overall process.

Our practical experience, onsite skills and in-depth data analysis with modeling capabilities create an overall picture to help you get the most out of your entire operation.

Reuse l Repurpose l Recycle l Revive

4. Modernize & extend life phase

Cost-effective, innovative, sustainable solutions to the very end

Modernizing or upgrading equipment is a cost-effective and sustainable manner to update aging equipment to the latest more efficient technology and increase capacity to continue production adding to the life of your plant and profitability.

Refurbishments can restore and optimize your equipment to its original condition to continue production.

Other ways to increase the lifetime of your plant is by making use of mobile filters, reserve filters, and modular container systems which can be charged at a monthly fee to suit your timeline.

We will manage the change project providing a full turnkey solution, from planning to implementing and ramping up.

The future of mining depends on sustainable practices that contribute to the equitable development of the community and ecosystem while enabling modern life. With the introduction of new-age dewatering technology, Metso is committed to offering productive and eco-efficient solutions to its customers. We help mining companies not only to maximize water recovery but also help reduce the footprint of tailings dams.

- Up to 90% water recovery with high-performance filters

- Up to 50% less floor space increasing safety and lowering CAPEX with Inclined Plate Settler (IPS)

- Improved filtration efficiency into fine and coarse streams with MHC™ Series Hydrocyclone

- Reduced reagents using thickeners with Reactorwell™ technology